SimWell Consultation Services

Work with a team specialized in solving complex planning and scheduling problems with advanced analytics.

Passionate Specialists Who Love to Solve Hard Business Problems

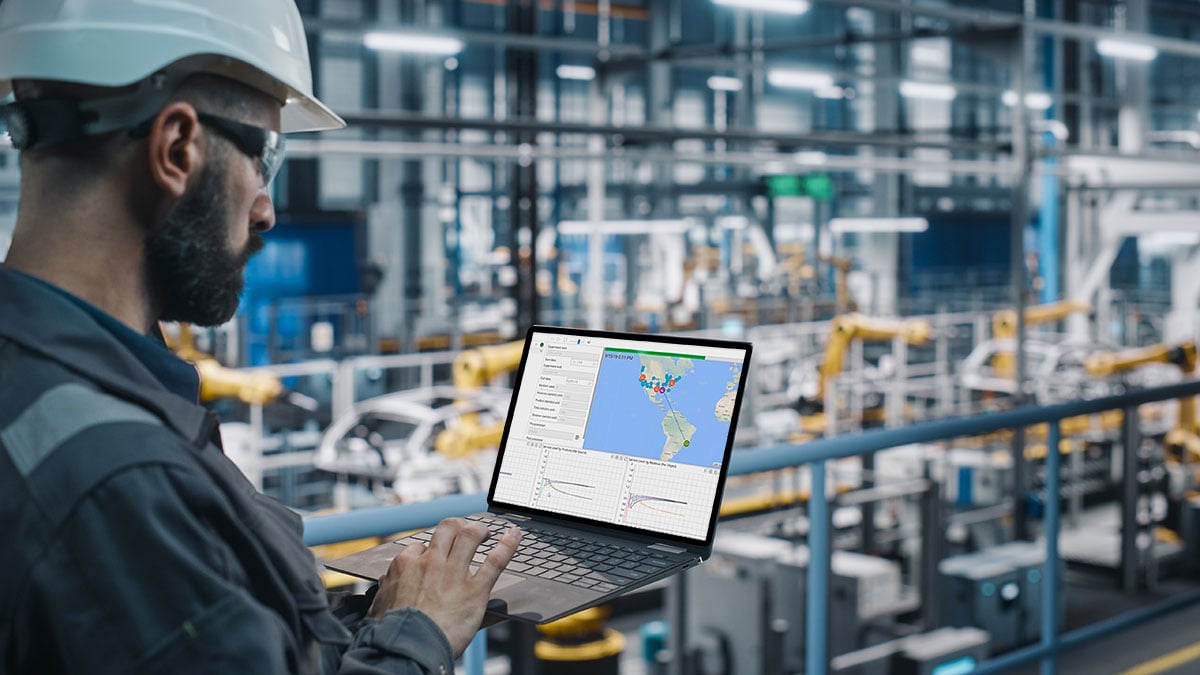

We know how challenging it is to run your operation when so many complex and ever-changing variables are at play. With decades of experience in simulation, optimization, and data science, we work with your team to develop Decision Support and Decision Automation solutions.

Simulation

Optimization

Artificial Intelligence

Data Science

Data Engineering

Advanced Analytics

Technology to Solve Your Most Complex Business Challenges

The world is rapidly evolving, and operations are becoming more complex. If you're dealing with challenges you've never seen before or fielding questions you just don't have the tools to answer, our team can help. We partner with customers to build turnkey solutions for their businesses.

Unlock Your Potential with SimWell Consultation

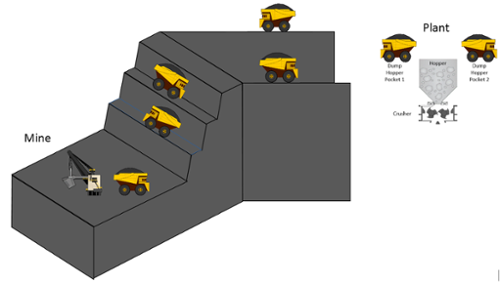

Expedite even your most complex operations. A manufacturing company wanted to accelerate processes and increase production to keep up with growing demand. With SimWell's advanced simulation technology, the team can now visualize their entire production process, from the first arrival of the units to their exit, and test for a variety of scenarios to improve production plans.

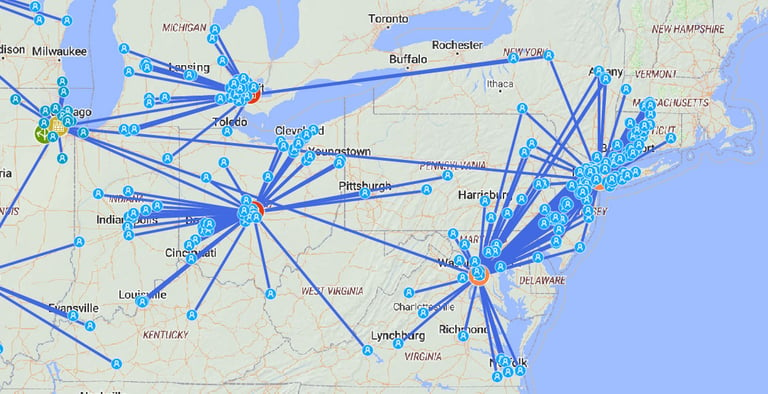

Leverage the power of simulation software. For supply chains, transportation hubs, and shipping companies, cost reduction is key to long-term profitability. Using Arena's simulation software, SimWell helped a gas distributor in Western Canada size its fleet of tractors and trailers, test for operational efficiency, and identify and minimize risk. Thanks to Arena, the team fulfilled each of these objectives while also driving down costs.

Manage logistics from a single dashboard. Many organizations use siloed reporting tools to manage data, like an equipment rental company SimWell partnered with. This outdated process quickly becomes time-consuming and labor-intensive. With SimWell's advanced Excel expertise, the rental company can now manage all of its financials from a single, centralized dashboard in a matter of minutes.

Maximize Your Business Growth Potential When You ...

Turn Insights into Action

Our advanced modeling tools provide the relevant information you need to make more informed decisions, faster.

Know What Will Work & How

Boost Efficiency & Reduce Risk

Many moving parts impact your operations. See where you’re losing money, time, and energy, and understand how to make improvements.

.png?width=768&height=512&length=768&name=Rail%20Yard%20(2).png)