Case Study: A large apparel company uses simulation to understand its strategic storage and throughput capacity needs for the future

The Challenge With Strategic Capacity Estimations

Storage and throughput capacity planning is a critical and challenging activity for most companies.

Understanding how much capacity is needed in the coming years to serve their market and securing it on time enables companies to meet customer demand, balance supply and demand, manage uncertainty, improve supply chain resilience, optimize financial results, and support growth.

However, there are many questions that operations and supply chain leaders must answer as they search for a solution to determine how much capacity they need. For example:

- How do we translate the company’s long-term strategic forecast into throughput?

- How do we account for peaks and valleys in capacity requirements due to the variability in demand and supply?

- How do we factor in our supply strategy?

- How do we account for unsold or slow-moving inventory?

- How do we account for the unique functions of our logistics nodes?

- What levers do we have to reduce capacity requirements and total inventory?

- How do we convince our stakeholders that our capacity requirements need to be approved?

The Need For a Robust Capacity Model

Our client's capacity planning challenges were similar to those of other apparel companies that need to ensure they have enough capacity to meet demand. Expanding warehouse capacity is costly, and companies may find themselves constrained by limited space. As their product offerings and demand grow, managing storage space efficiently becomes a significant struggle, and projecting capacity develops into a complicated task.

Simple approaches to projecting capacity fell short as they fail to capture realities inherent to the apparel business such as long and unpredictable supply lead times, the need to receive supply in large lumps at the beginning of the season, and the additional capacity requirements due to slow-moving and obsolete stock.

Our customer realized that needed a robust solution that would allow the company to capture the complexity of their operations, the interrelations of the logistics flows, and the inherent variability of the business.

The objective of this solution was twofold: to create a centralized process that would help convince stakeholders about the capacity requirements needed taking into account existing policies, and to assess the potential repercussions on the supply chain in the next ten years due to the introduction of new distribution centers or the discontinuation of current facilities.

A Solution Tailored to The Apparel Customer Needs

SimWell worked collaboratively with the customer to develop an advanced simulation model capable of accurately replicating the client's inventory warehouse supply chain, incorporating the unique supply and demand strategies they use. This data-driven model stands out for its exceptional:

- Accuracy and validity, since it was validated and calibrated against real data to ensure they provide reliable and trustworthy results

- Ease of use, as it is able to use as input the strategic demand projections

- Agility, as it incorporates on-screen parameters to adjust quickly demand and supply aspects

- Flexibility and Adaptability, since it allows for swift modifications to the supply chain structure

- Performance and efficiency, as it was designed and built to run quickly so the user could create multiple scenarios and compare them at ease

Furthermore, the users enjoy other unique features such as

- The ability to dynamically adjust and being able to estimate and track unsold inventory quantities that eventually become obsolete in the market

- The ability to dynamically define the desired number of weeks of coverage for each warehouse, allowing for precise customization of inventory levels

This granular control empowers the user to effectively manage the behavior of the supply chain under varying circumstances.

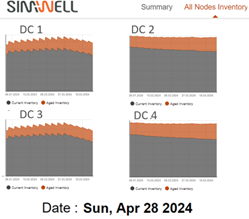

The model is also impressively fast, processing a decade's worth of data in less than 30 seconds (when running at maximum speed). It also features an easy-to-use built-in dashboard that allows real-time monitoring of inventory levels and other key performance indicators (KPIs) while the model is running.

This information is then collected and stored in output files, facilitating the generation of comprehensive reports or providing the option to explore the entire dataset using the integrated PowerBI dashboard.

Robust Models That Convince Stakeholders to Take Action

The inventory supply chain simulation model allows for capturing the complex dynamics of the supply chain, conducting what-if analysis to test different scenarios, mitigating risks, evaluating performance, and facilitating continuous improvement.

The simulation model provides a holistic view of the supply chain system, enabling analysis of interconnected nodes, inventory levels, and customer demand patterns. It helps the client make informed decisions about production capacity, distribution strategies, and investment in facilities.

Additionally, the model provides a flexible and objective means to assess performance, measure key performance indicators, and adapt to changing market conditions.

Our customer was able to create the desired solution to estimate storage and throughput capacities, develop and test critical scenarios, and convince stakeholders to take action!

Are you interested in being able to estimate your capacity requirements and convince your stakeholders?