Design and Operate Your Warehouse for Optimal Efficiency and Productivity

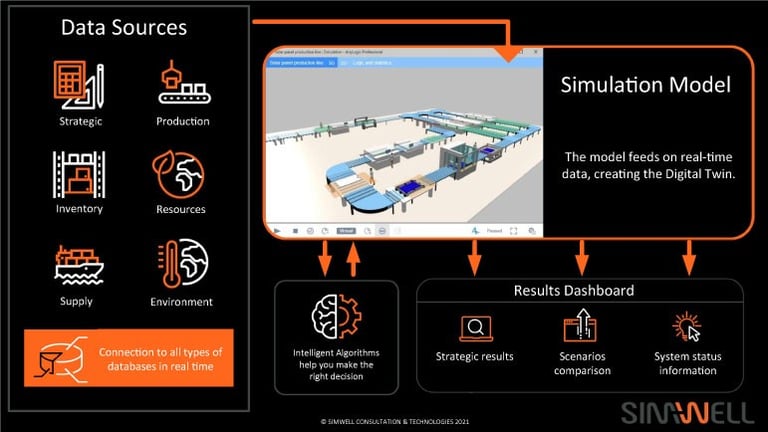

Whether you're building a greenfield warehouse or introducing automation and robotics into your distribution center we'll help you get it right the first time. We use simulation, optimization, and digital twin to build decision support and decision automation tools.

Distribution Centers Aren't Simple Anymore

As companies face increasing demand and labor shortages, many are turning to automation, robotics, and other technologies. However, despite big investments, these changes often fail to meet expected outcomes. Why does this happen?

The distribution center is a complex system. It's difficult to predict how the operation will perform when changes are made. That's where we come in. We use simulation, optimization, and digital twin technology to test changes in a risk-free environment, compare scenarios, and ensure that every new investment leads to the intended outcomes.

Order Flows

Compare order flows through the DC including order types (Single Item Orders vs Multi Item Orders), how orders are released into the DC (Order Batching), product slotting, resource assignment, and cut off times for different types of shipping.

Automation and Robotics

ROI Analysis

Analyze the return on investment before introducing new technology like automated systems and robotics, CapEx projects, or operating policies like picking strategies.

Layout Optimization

Optimize the layout of your warehouse to reduce travel time, improve picking efficiency, and increase throughput.

Labor Optimization

Order Picking

Compare picking strategies to increase efficiency and reduce the time it takes to fill customer orders.

Routing Optimization

Optimize routing within your warehouse to ensure you have the right number and type of resources to meet your business objectives.

Slotting Location

Comparing slotting scenarios and optimize SKU location to improve order retrieval and fulfillment rates.

Warehouse Capacity Planning

Determine capacity and throughput improvements whether you're building a greenfield site, changing a layout, or introducing automation.

Inventory Optimization

Compare inventory policies in a risk-free simulation to determine optimal inventory levels for each SKU in your warehouse, reducing stockouts and overstocking.

Shipping Dock Optimization

Optimize the number of dock doors, loading policies, and more to reduce wait times and increase throughput.

Truck Yard

Simulate daily truck yard plans to remove bottlenecks and improve throughput.

Simulate Your Distribution Center

Simulation provides a risk-free environment to test changes in your warehouse or distribution center. Whether you're introducing automation and robotics, planning a picking strategy, or designing a greenfield from the ground up simulation will help you get it right the first time saving you time and money.

Explore How Simulation Modeling Helps

Analyze Your ROI Before Making an Investment. Simulation helps you assess the risks associated with introducing new automated systems. By simulating different scenarios, you can identify potential bottlenecks, quantify KPIs like utilization and throughput, or compare different strategies in staffing, picking, slotting and more.

Optimize Your Process with Automation and Robotics. Simulation can help you optimize the processes involved in introducing automation and robots into your warehouse. By simulating different scenarios, you can identify potential bottlenecks and inefficiencies and optimize the introduction of new technologies.

Layout Design and Capacity Planning. Simulation can help you design the layout of your warehouse and determine capacity of the facility. By simulating different layouts and resources, you can identify potential issues, optimize the placement of new systems, and determine the optimal number of people, equipment, and automation.

Maximize Your Business Growth Potential When You ...

Turn Insights into Action

Our advanced modeling tools provide the relevant information you need to make more informed decisions, faster.

Know What Will Work & How

Boost Efficiency & Reduce Risk

Many moving parts impact your operations. See where you’re losing money, time, and energy, and understand how to make improvements.