Case Study: A Leading Manufacturer Implements A Supply Chain Digital Twin Guided By SimWell

Motivation For Digital Twin Implementation

Founded in 2015, ICP Group has scaled rapidly through organic and acquisition growth into one of North America's largest coatings, adhesives, paints, and sealants manufacturers. Following this impressive growth, the leadership realized the latent opportunities to rethink their logistics network and create the capabilities in-house to conduct periodic logistics network optimization exercises that will drive improved performance.

ICP’s leadership recognized that building capabilities in-house to conduct thorough logistics network optimization would not be easy. Like many other leading manufacturers, ICP handles

- Multiple production facilities

- Multiple distribution centers

- Hundreds of customer locations

- Thousands of stock-keeping units (SKU)

However, the need to implement a technology to conduct network optimization and building their people’s capability was imperative to tackle the growing demand, competitive market, and the persistent supply chain disruptions that any manufacturer kept suffering after COVID-19.

The leadership recognized that if they overcame the challenges, they would be able to achieve critical opportunities such as:

- Improve end-to-end supply chain visibility

- Optimize total cost to serve

- Improve supply chain resiliency & flexibility

- Accelerate growth

The leaders started searching in the market a solution that would help them meet their goals, and they decided that the best fit would be to develop a supply chain digital twin to build up network optimization capabilities around people, technology, process, data, and governance.

The leaders realized that to be successful, they would need to receive the assistance of a leading technology partner to create and implement the roadmap for supply chain optimization and operational excellence. The leaders decided to partner up with SimWell to develop their supply chain digital twin.

ICP And SimWell, A Synergetic Alliance

A critical goal for ICP was to develop its own in-house network optimization capabilities by building and learning how to effectively use a supply chain digital twin. Their leadership recognized that they did not want:

- Another PowerPoint presentation developed by consultants that would be outdated by the moment is presented

- Neither they wanted to be in a situation where they would be handed over a black box model that could be hard to understand, use, and maintain

ICP had the right mindset to start their digital twin journey and their leadership was willing to invest the resources to be successful. Hence, they decided to find a partner to would be aligned with them to help them develop their capabilities.

Simwell was selected from a pool of highly qualified competitors due to:

- A very high degree of experience guiding digital twin implementation

- Combined expertise in simulation, optimization, and advanced analytics

- Multidisciplinary and globally distributed team to adjust to time zones

- A culture to surpass expectations, innovate, demonstrate empathy, and make the client the hero

SimWell experience, skills, and culture were considered the perfect fit to help ICP to develop its digital twin and tackle their most pressing supply chain design challenges in three areas

- Supply Chain Footprint

- Asset Utilization

- Transportation and Distribution

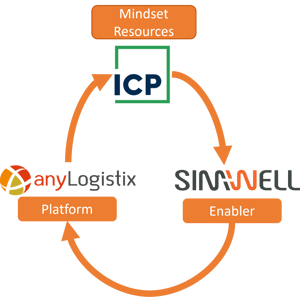

The digital twin journey got started using SimWell as an enabler, and anyLogistix as the platform giving capabilities for

- Consolidating and standardizing operations

- Seamless transition from greenfield analysis to network optimization

- Scalability and flexibility

Building Blocks Of A Digital Twin Journey

While ICP and SimWell worked collaboratively to develop ICP’s digital twin, two key success points for the project were the project management methodology and the digital twin architecture.

SimWell follows an agile approach while developing solutions, as we have learned that enables the project to be focused on the customer’s top priorities at all times and delivers timely results. The constant development, validation, verification, and testing, together with the constant customer feedback was critical for developing a useful digital twin tailored to ICP’s needs.

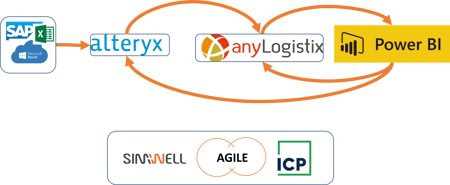

The architecture was the other key factor that enabled the success of the project. ICP and SimWell collaborated to decide what architecture fitted better ICP uniqueness, and how that architecture would deliver a sustainable digital twin. The decision about architecture was to

- Connect inputs to the digital twin engine (anyLogistix) using an ETL tool (Alteryx)

- Use anyLogistix as the platform to support the digital twin

- Use a valuable visualization tool (PowerBI) to quickly see the results from the models

The reasons to use these three key pieces of architecture is because a functional digital twin must:

- Have a way to consolidate and clean up data systematically

- Have a powerful optimization and simulation tool for scenario planning

- Allow users to see results quickly and provide their feedback

Results

ICP and SimWell built together the supply chain digital twin that allowed ICP to conduct rigorous GFA and NO analyses to provide multiple options for review. ICP’s continued network optimization mindset drove journey success, while SimWell’s supply chain and technology partnership helped reduce the journey uncertainty to deploy a sustainable solution.

SimWell assisted ICP in building a baseline to capture ICP’s operations and to build up scenarios.

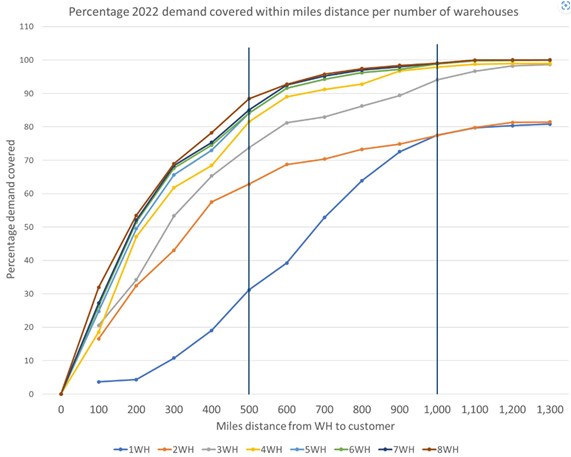

The initial models allowed ICP to identify potential distribution center locations for a certain part of North America by conducting a green field analysis (GFA) and evaluating how many distribution centers would be required to cover their market within a certain distance of the customer.

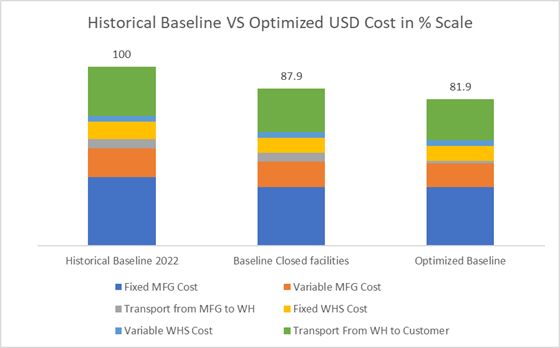

Additionally, conducting network optimization, ICP was able to compare the financial and operational results of different models, to find what network configuration was more appropriate.

The initial models discovered a saving opportunity of 18% comparing the model results to the historical baseline, and a 7% comparing the final proposal to an adjusted model that accounted recently discontinued facilities.

Implementing a digital twin is a journey, and finding a reliable partner to help you be successful is critical.

See how SimWell can help you make critical business decisions with confidence on many aspects of supply chain management and operations. On this page, you’ll see our expertise in simulating and optimizing supply chains that can make you the hero for your team, your organization, and your community.

You can see how this case study was presented in the anyLogistix 2023 conference here.

What are you waiting for? Book a call and see how we can help you.