Case Study: Unlocking Simulation and AI to Optimize Quick Service Restaurant Operations

Convenience is the Pillar of Fast Food, Lean and Optimal Operations Are the Footing of Convenience

Operating a Quick Service Restaurant (QSR) is not a trivial process. Many stochastic variables interact with one another in such a dynamic way that it becomes challenging for managers to optimize daily operations.

- Which is the optimum number of employees that can satisfy customer demand?

- How much equipment will be needed to operate a store efficiently?

- Which is the best layout that will minimize traveling distances?

These are just a few questions managers face during capacity planning sessions before the launching of a new store and on a regular basis, keeping continuous improvement in mind.

The previous becomes a complex optimization problem to solve. Costs, walking times, processing times, wastes, queue lengths, and delays need to be minimized. On the other hand, revenue, throughput, and utilization rates need to be maximized. Many configurations and scenarios can result from the interactions of both, stochastic and deterministic variables, in such a complex system with multiple agents.

Quantifying the gain of change to a given configuration of a store is difficult without testing it in a real-life situation. However, making such tests in real life is costly and may lead to decreased speed in service, and thus, decreased throughput. As a solution, SimWell used dynamic simulation models and an artificial intelligence brain for testing improvements in a risk-free digital environment.

How much more can it take before it break?

Before launching a new store layout or concept, the customer had to perform multiple feasibility analyses and tests to evaluate a new store design while validating if it would be capable of satisfying the forecasted demand. In addition, the customer was highly interested in calculating the “breaking point” of any new store (i.e., the maximum achievable throughput for a given configuration). Previously, the customer had to build the store's prototypes within their testing labs and conduct real-life simulations with real employees and equipment while consuming physical resources, time, and money to conduct such analyses to answer as many unknowns as possible.

After multiple real-life simulations were conducted, and with many more simulations to test, the customer realized that their current testing process felt short for their initial scope and that a significant number of resources were being utilized before launching a new store. The previous led the customer to seek more innovative testing solutions.

And then SimWell was called in

They contacted SimWell to leverage simulation technologies and artificial intelligence to accelerate their testing process in a risk-free digital twin environment in a more efficient way. SimWell was entrusted to build simulation models of store prototypes that matched their lab tests as close to reality as possible, obtain results, and propose alternative solutions to support their feasibility analyses.

An Integrated End-to-End Solution

To tackle this challenge from multiple angles, SimWell developed multiple solutions that were integrated at the end in a master deliverable:

- SimWell developed a discrete-event and agent-based hybrid simulation model of multiple stores prototypes that allowed the customer to determine, with confidence, the maximum achievable throughput and utilization rates while configuring multiple scenarios and changing variables values such as product mix, channel mix, customer arrival patterns, employees’ deployment, employees’ roles, and equipment amount.

- SimWell helped conduct a time-and-motion study to capture the overall process and real production times of items in an effort to simulate them as close to reality as possible, rather than hard-coding their values with raw estimates. In addition, SimWell developed a website that stored the results in a database easily accessible to the customer stakeholders, where they could upload more replicates and/or new entries of future items.

- SimWell trained an artificially intelligent brain capable of determining the optimum variables’ values based on multiple given sets of conditions. In this way, the total number of experiments to be conducted decreased significantly and allowed the customer to find answers in a much faster and more reliable way.

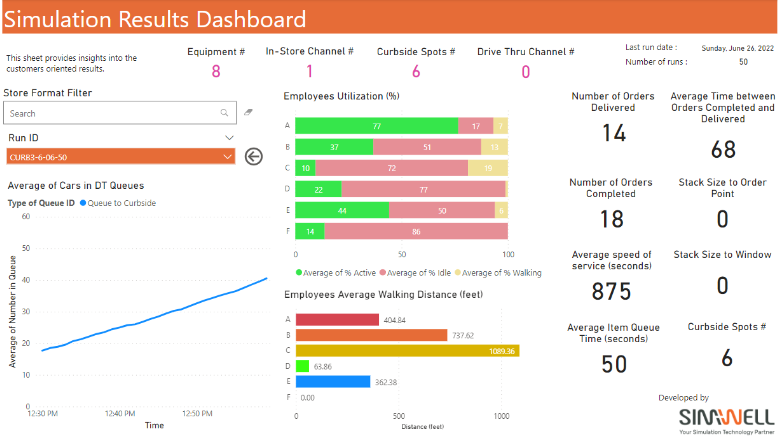

- SimWell developed a dynamic Power BI dashboard containing the results, outcomes, and key process indicators (KPIs) from the simulated scenarios with their corresponding descriptive statistics, confidence intervals, visuals, tables, and more, that could be easily understood by a non-technical audience.

Outcome That Led to Long-term Partnership

SimWell's use of simulation technologies and artificial intelligence allowed the customer to test a variety of new store prototypes significantly faster, without the use of personnel and material resources, and with a variety of configurations to understand the outcomes of multiple what-if scenarios. For all the simulated stores, the following KPIs were improved: throughput (i.e., total number of orders delivered), total speed of service, total orders production time, items processing times, the average waiting time to place an order, average ordering time, average customer time at the window, average order production queue time, average order time between completed and delivered, employees’ active time, and queue lengths.

In the same way, the trained artificially intelligent brain was able to successfully determine the optimum number of employees per shift with their corresponding assigned roles, resulting in a balanced workload across all the team members with reduced walking distances and without significant idle times. All the previous resulted in optimized store prototypes with higher revenues, decreased labor costs, and higher customer satisfaction.

Impressed by SimWell’s work, the customer decided to establish a long-term partnership with the company to help them simulate any future store prototypes, including new equipment technologies, continuous improvement initiatives from the company, and alternatives that would challenge and break the status quo.