Case Study: Cookies United Production Scheduling Optimization Tool

Overview

Cookies United is a premier manufacturer of high-quality baked goods that produces hundreds of cookie SKUs using multiple production lines. Some SKUs go through multiple production lines and some SKUs are assembled using other SKUs.

Cookies United contacted SimWell to create a tool that will allow the planning team to generate a master production schedule for one year at a monthly granularity. Cookies United wanted to have a flexible tool that they can configure using input sheets. The runtime for the tool should be less than 5 minutes so that they can run multiple scenarios in a short time.

The Business Objective

The problem statement is to make a tool which creates the master production schedule, considering the demand, production line capacities, labor capacities, processing times and SKU, production line feasibility, as well as production costs.

Cookies United had more than 400 products, 1 production facility, 5 production lines, and around 250 employees. The client currently does the planning manually in Excel. It is time-consuming and does not guarantee the best schedule. The plan is as good as the planner who is working on it. There is seasonality in the demand and there is a need for pre-build as there is not enough capacity to meet the demand during the peak demand months.

The tool must be flexible to handle new SKUs and production lines.

Solution

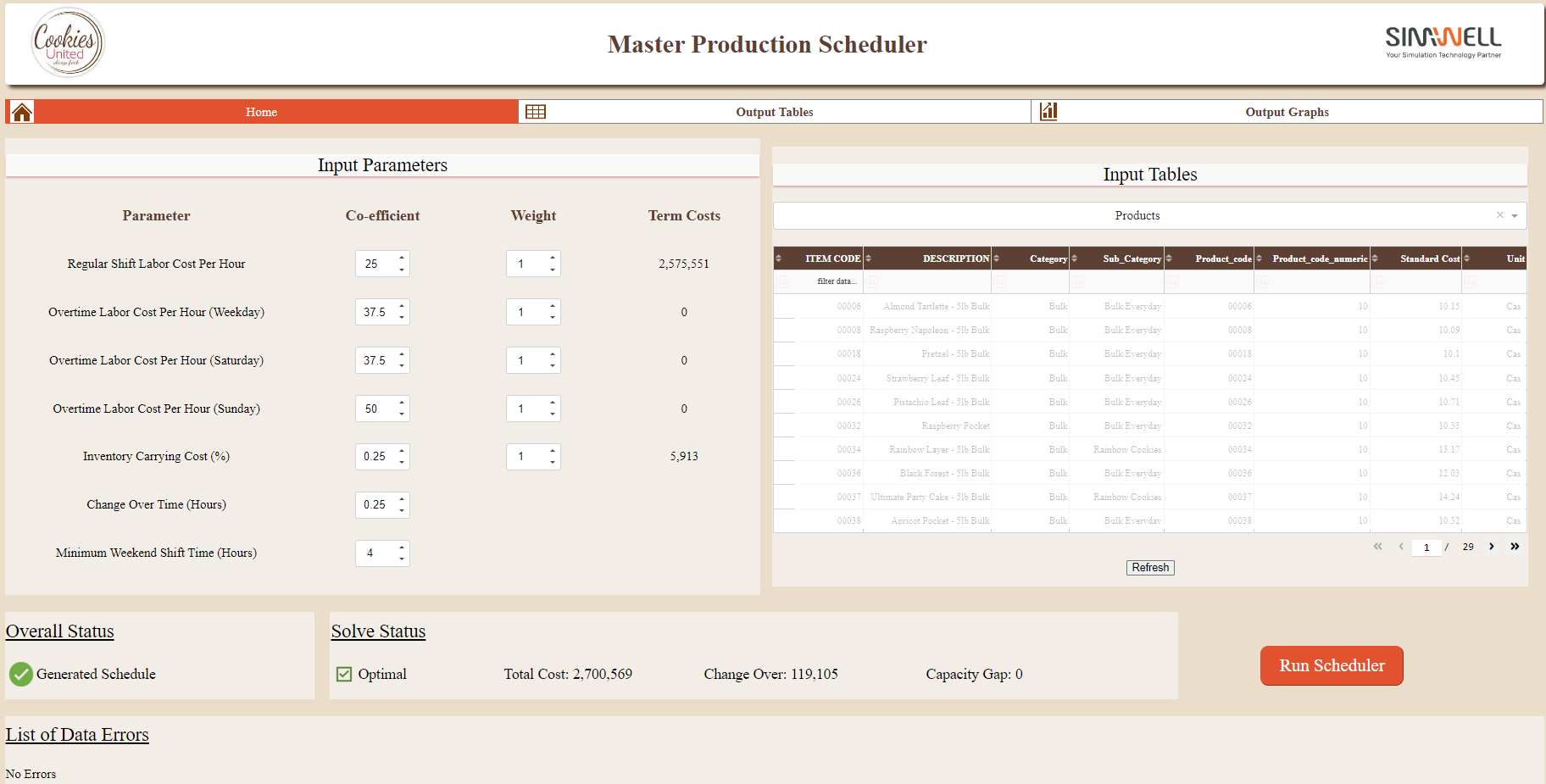

SimWell developed a master production scheduling tool in Python using various packages. The main engine for the solution was an optimization model built using PuLP package. The solver used was CBC, which is the default solver available with PuLP. A Mixed Integer Linear Program (MILP) was built that is flexible enough to generate production plans at any time granularity for all products, lines, and planning horizons. Cookies United currently uses the tool at a monthly granularity and for 1 year planning horizon and the data is set up accordingly.

The tool can consider all costs such as changeover costs, overtime costs, and inventory carrying costs. It considers all demands and constraints such as SKU to production line feasibility. It creates a production plan that meets the demand with the minimum cost.

A web app was built in Dash (Python package) for users to configure the costs and weights of the objective function, review the input data tables and launch the optimizer. The user is able to see the output results and charts and dashboard on this same tool.

The Results

With the production scheduling tool developed by SimWell, Cookies Unite can generate the optimal master production schedule in minutes. The model user can change the input settings and run multiple scenarios and select the best one.