Why Slow Decisions Quietly Destroy Value

Welcome to Speed is Strategy, a 3 part series on the role of indecision in business success. You're reading Part 1.

The demand forecast spikes. Rates rise overnight. Everyone knows what to do, but approvals take a week and the capacity window closes. The trucks still move, the spreadsheets update, and value quietly leaks away.

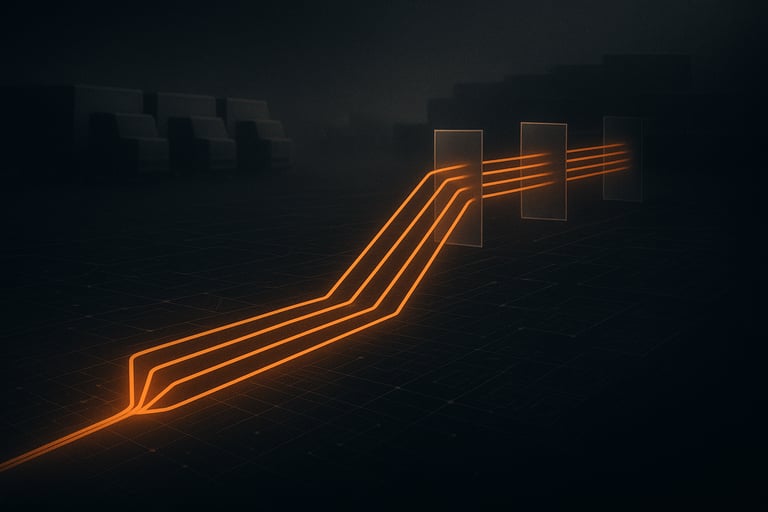

The hidden cost of decision delay lies in the time between recognizing a problem and executing the fix. In lean terms, it’s waste. In product development, it’s the Cost of Delay. In operations, it’s where margin disappears.

Timing to Decision Is a Variable

Operations research has been quantifying this for decades. Zhan’s 2022 model of delay time in supply chain decisions showed that profit and goodwill fall sharply as delays grow. Reinertsen’s Cost of Delay work found that even a one-week slip can erase one to three percent of total value. A 2021 Economist Intelligence Unit survey of 400 operations leaders estimated that disruptions cost firms six to ten percent of annual revenue, much of it due to internal response time lagging external events.

If that sounds abstract, put it in your own ledger. A one-week delay on a sourcing switch often equals a month of lost freight savings. The later you act, the less your data (and your advantage) are worth.

A Real Example: The Suez Slowdown

When the Ever Given blocked the Suez Canal in 2021, roughly twelve percent of global trade stopped. Each day trapped about 9.6 billion USD in goods. That is 400 million USD in delayed value every hour.

Every logistics team watching faced the same question: reroute or wait. Some rerouted within hours, accepting fuel and insurance costs. Others waited for corporate clearance. When approvals came, rates had tripled and ships were queued for weeks.

The canal was a physical chokepoint. The bottleneck was decision velocity. Some companies paid for fuel. Others paid for hesitation.

When we measure why teams stall, the same three bottlenecks appear again and again.

The Three Sources of Delay

|

Source of delay |

What it looks like |

Typical owner |

Measurable fix |

|

Organizational |

Waiting for alignment or approval |

Leadership chain |

Decision clocks and guardrails |

|

Analytical |

Endless spreadsheet updates, dashboard refreshes, and recurring meetings where decisions stall |

Analytics or operations team |

Scenario management, automated data refresh, and model runs |

|

Execution loop |

Detect → decide → act cycle too long |

Operations |

Event triggers, automations and/or policies |

Each category tells a story about how organizations lose speed. Leadership stalls for consensus. Leadership stalls for consensus. Analysts wait for the issue to arise to build the models.. Operators wait for triggers that should have fired automatically. Add them together, and you get a single metric: the Decision Latency Index — the total time between signal and response.

That delay isn’t theoretical. It’s measurable in lost throughput, excess freight, and missed margin.

Turning Time into Money

Cost of Delay = Value lost per day × Days delayed

If your system loses $150,000 a day in throughput and you wait nine days to act, that’s $1.35 million gone. Most teams already count demurrage and late-shipment fees. The hidden losses live inside approvals, emails, and meetings that never quite end.

Decision Speed as Competitive Asymmetry

Decision speed compounds like interest. The faster you decide, the faster you learn. Better learning sharpens forecasts, which makes the next decision faster still. Over time that cycle becomes an advantage your competitors can’t copy.

Research on organizational clock speed shows that companies that adjust decisions twice as fast as peers generate two to four times higher shareholder returns. In other words, reaction time is strategy.

The Takeaway

Your network, carriers, and software look the same as everyone else’s. What sets you apart (or exposes you) is how long it takes to decide.

Decision speed isn’t luck or culture. It’s design.

And in a world where everyone has the same data, timing is the only unfair advantage left.

Continue the series: Read Part 2, Confidence Without Certainty, to see why speed depends on trust, not just analysis.