Case Study: An equipment rental company uses Advanced Excel expertise of SimWell for their dashboard

SimWell’s customer is a company specialized in top international designer shoe collections and exclusive street fashion. Browns Shoes wants to optimize their current Automated conveyor system for the order picking and shipping processes. The client’s shoe distribution center has an automated storage and retrieval system (ASRS).

Under some circumstances, the picking is slowed by the automated conveyor which reduces the productivity of the picking stations. The client wants to understand the relations between the variables of the system.

Summary of the process

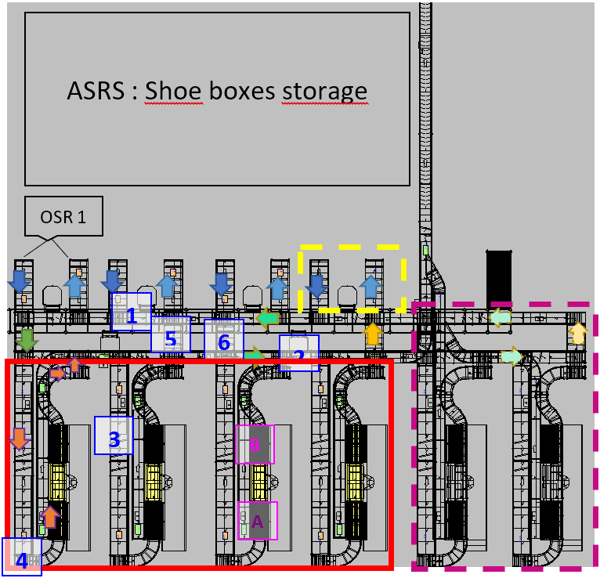

Once an order is selected, a box which includes the family type required by the order will exit the OSR (automated system that moves the boxes in the storage). Then, the box will enter the conveyor 1, then follow the green arrow, then enter the conveyor 2. When the shoe box arrives next to the conveyor related to the picking station designated, it will enter one of the 4 conveyors (one of them is indicated as #3 in the picture). Then, it will follow the path of the orange arrows. When the box arrives at the picking station, the employee removes the small box required by the order and put it in the order box (picking action). Then, the box will continue the way to the conveyor 2. The box will enter the conveyor 1 by following the yellow arrow and then, will enter the OSR from where it came from and return to the ASRS.

A video of the simulation has been recorded. It shows the system with its actual parameters.

Simulation

Using the Arena simulation model, the analyst can identify the bottleneck of the system. By using the Excel user interface, the analyst may change any parameter in order to optimize the system and increase the productivity of the picking stations.

Scenarios

Using the Arena simulation model, the analyst can test all the scenarios and choose the best option which the highest productivity per employee at the picking station:

- Adding 2 picking stations

- Activating the shortcuts

- Adding the fourth OSR

- Extending the loop’s conveyor length without adding a picking station

- Any other options

A useful animation and some trustworthy results

Once the modeling completed, the model was delivered to the customer so that they can change the parameters and find the best scenario to apply in their current system. The customer was impressed by the realism of the 2D animation in Arena and with the process’ accuracy, which proved totally comparable to reality.