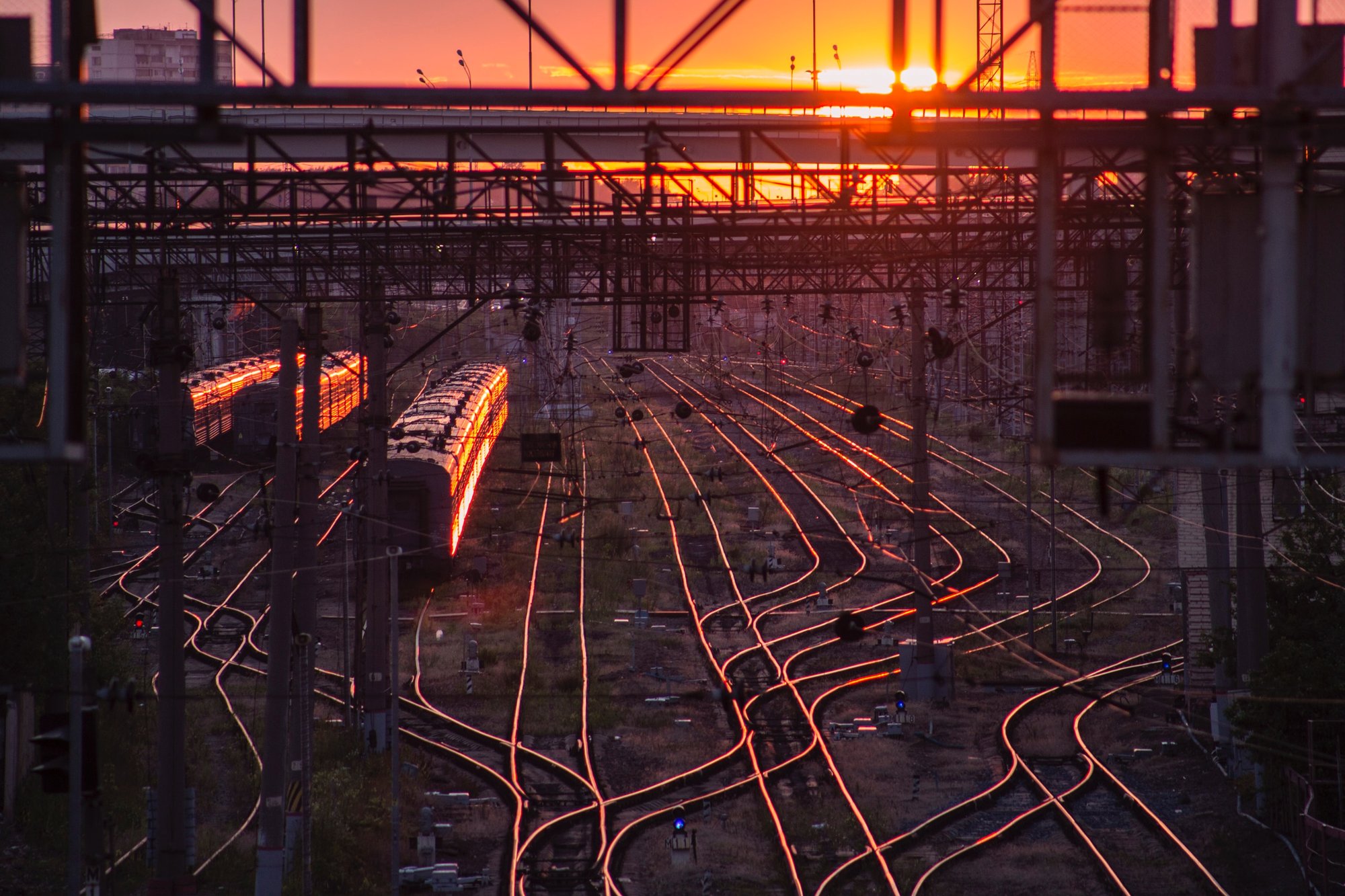

Case Study: SimWell Builds a Digital Twin Capable of Giving a Railway Company Insights Into Their Operation & Decision Making

Summary

SimWell was contracted to develop a Railway Digital Twin Simulation Model that would handle a 2-week to 3-month plan and would simulate everything from the facilities loading the trains, the railway and train crossings, all the way to the unloading of the train and their maintenance. This tool was meant to be used operationally at weekly meetings to validate and optimize the plan and was required to be able to output results within minutes if not seconds. The requirements would also be subject to changes along its development, as to match the ongoing changes to the actual system.

This ask was not insignificant, and SimWell was selected as we use a proprietary methodology of Simulation and Digital Twin development called EDP that allows for incremental progress, a flexible solution that can easily be turned around or refocused, and a close relationship with the client to ensure we stick closely to their needs and assist them in finding solutions both for the development of the tool and for their data and process needs. This methodology was critical in ensuring the correct path was taken and allowed us to quickly identify with the client how to best transition to different tools once a change in their system requirements necessitated an additional dimension to their Digital Twin.

Background

Railway systems are nothing new, and there are multiple solutions on the market to help manage them. Meet-pass planners systems, for example, are used to help railway controllers manage and optimize train meetings. Production planning tools can be used to predict when a train will be required at production facilities, or how long it will take for said train to be unloaded, and resource management tools to assess human resource availability and how to best utilize them, BUT there are no tools on the market capable of answering all of those questions and more on a daily basis. Only a tailor-made Digital Twin can provide this all-in-one solution, all while assisting in identifying potential issues as well as opportunities in the future.

Furthermore, this client required a solution that could be brought up step by step and not in a single one-size-fits-all package, as those solutions can take years to develop and become partially or entirely obsolete by the time they are completed. They also required a partial solution in the very short term which would then be built upon, adding nodes and layers working towards the final solution.

Solution

The solution provided to the customer was to build out the most critical and urgent sections of their operations first, as well as implementing a simplified version of their other services to ensure end-to-end visibility of their process, without the difficulties of reproducing an entire Digital Twin of the entire system. The railway itself on which the trains traveled was to be fully fleshed out with very few details spared, but the other operations such as production, shipping, maintenance, and resource management would be stripped-down versions of their real-world counterpart.

Our approach allows for iterative development that allowed us to build first the railway and its associated operations, before adding more sophistication to the core of the digital twin as we worked towards the final solution. As we identified additional needs for complexity in the adjacent systems to the railway, SimWell was able to shift focus and reprioritize, all in a short schedule to ensure the greatest return on investment in the short term for the client, without doing so at the cost of the long term, as our methodology and development philosophy was designed with work in parallel and modular thinking in mind.

Results

The outcome of the project was a railway Digital Twin that fulfilled the client's need and allowed them to simulate scenarios within seconds and get preliminary results for the railways that included all the information they already had and used, but also provided new insights using the data that they already had on hand but were not able to effectively use.

Our earliest deliverable product (EDP) framework allowed the client to get comfortable with the tool, learn what worked for them, and what required additional attention. Once those items were settled the client’s feedback was that the tool provided good insight and was on the right path, and to continue our iterative process to keep adding on functionalities.

This success made possible the continuation of said project to the future phases where SimWell will be working towards implementing the larger scale solution that includes a larger scope of operations both in the railway system and in its inflow and outflow systems, as well as eventually optimization of the entire process chain with an AI integrated solution.