Smarter Supply Chain Planning with anyLogistix

When customers search for ALX they search for the following reasons:

- Solve a critical business challenge in the supply chain.

- Reduce software costs by finding software to meet basic needs.

- Consolidate several supply chain design tools.

- Want to build agility into their supply chain services to make faster data-driven decisions to differentiate from their competitors.

- Seeking to build a resilient supply chain.

- Opportunities to solve new problems and go deeper in supply chain analysis for clients with different features.

- Improve their current tool they are for solving supply chain issues. Learn how organizations are converting from software like Excel to anyLogistix to make data-driven decisions.

AnyLogistix is a powerful tool that brings simulation and optimization into one place. One thing that every anyLogistix user has in common is that there is always more they can do with anyLogistix to save money, improve service, and reduce risk.

Here are 5 things you might not know about ALX and that will make your business faster, resilient, and more profitable.

1. Supply chain agility with anyLogistix

It is no wonder why AnyLogistix is turning more heads than ever before. As Supply Chain’s become more volatile, organizations are looking for ways to keep up.

The strategies and tools they’ve used in the past took too long to build and didn’t capture the complexity of their supply chain. At best, this left business leaders underwhelmed with the tools they had to support key decisions, and at worst it prevented them from make good decisions while their competition moved ahead.

With anyLogistix, leaders do not have to compromise between fast and being effective. anyLogistix helps supply chain leaders make fast, data-driven decisions which ultimately builds agility into their operation.

With this type of agility, organizations can solve their most critical business problems when they come up and gain back their competitive advantage.

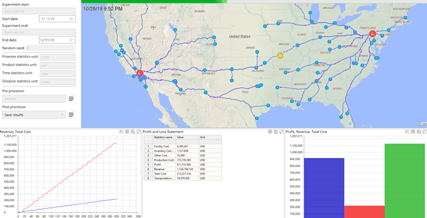

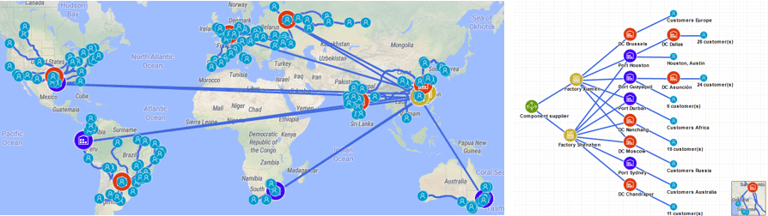

When you model your supply chain with anyLogistix, you can quickly analyze what-if scenarios to build strategic and tactical solutions for everyday problems.

Companies are looking for more effective and efficient ways to move their business quickly through any landscape and onboard agility as a new capability into their organization. Trailblazing supply chain leaders in various industries across many firms use ALX to build agility into their operation, which is something that they cannot do with any other tool on the market.

“With ALX I can be running a Simulation and then with a press of a button my model has been converted to run a Transportation Optimization. Then when I get my results I want; I convert my solution back into my simulation and see if the supply chain’s performance improved.” - Senior Supply Chain Analyst

2. Supply Chain Simulation with anyLogistix

Optimization is well known in supply chain, while simulation is growing quickly in this new, volatile world.

What’s the difference between supply chain optimization and supply chain simulation?

Optimization helps you identify what is the optimal answer(s) to distribute your goods throughout your supply chain for a specific period with certain assumptions.

While simulation will help in understand how a supply chain will perform over time providing a deeper dive of the impacts, and how to essentially improve and solve some those impacts prior to implementation.

Here’s a few of the questions you can answer with simulation.

- How will inventory policies impact our service level and P&L over time?

- When will we run out of capacity, and by how much?

- What happens when a pandemic, tariff, or strike shuts down a key supplier?

- How many trucks should I have and what customers should they serve? When does demand exceed capacity, and what should I do about it?

With simulation, you can consider the volatile nature of any supply chain to consider capacity planning in high season or shortages. This includes optimal storage locations, capacity, and inventory. Want to know more check this site on capacity planning.

Did you know that Anylogic’s Simulation engine has been around since 1998 and is now one of the most used simulation engines in the world?

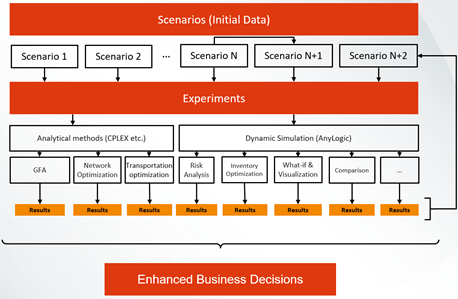

At that time, Supply Chain models were being optimized and designed on a blank canvas and due to its overwhelming use in supply chain problems the Anylogic company built AnyLogistix. So, when you are considering doing scenarios in simulation for inventory optimization, risk analysis (Interested in knowing more check this webinar or risk), comparisons, and other types of experiments. Then feel assured that you are working with the most used and trusted simulation engine in the market.

3. Day-to-day Supply Chain Decisions with anyLogistix

Most of our customers buy anyLogistix for supply chain design and planning, until they see the opportunity to use it as management tool.

When you have a model of your supply chain in anyLogistix, you can make tactical and operational decisions that move your business faster.

Imagine giving your managers a way to press fast forward on their decision to see how it will play out. How would that impact your operation? This can often save years of learning and inefficient spending.

Did you know that you build a model for your sourcing department to help them with their vendor selection process? Did you know that you can build a supply chain model to help manage your deployment process out in the field?

There are 100’s of uses for customers that we haven’t mentioned yet. Why consider ALX for managing? Consider Sourcing as an example. How can ALX benefit the department and/or the vendor selection process function:

- Select vendors that have a positive global impact on your supply chain.

- Select vendors that will perform well and align with your customer's expected service of availability and delivery. Reduce unnecessary volatility.

- Gain insight and flexibility to work contracts to favor and reduce risk.

- Understand if the supplier has the necessary capacity or if you need multiple suppliers for certain areas/territories of your supply chain.

- Derive your supplier planning needs to fulfill all demand.

- Improve the vendor selection process to be efficient by prioritizing suppliers and shortening the process by focusing only on the top suppliers.

- Optimize and analyze 100’s to 1000’s of sourcing options at any level: product, category, subcategory, or the whole supply chain in one scenario.

- Prioritize and focus on the big wins (large margin suppliers) from the beginning. Why wait 3-6 months to make revenue when you know the winners in ranking order.

- Capitalize on switching suppliers during the contract and evaluate if it makes sense to pay the penalty to make a profit within that period.

- Evaluate if the organization should continue purchasing from a supplier or produce the product itself. This includes ROI and breakeven point will occur.

- Prioritize the next product you should brand in your organization to get the best return?

We can add more to this list, but these questions provide a glimpse on how ALX can help in managing each segment/function of the business.

If you would like to know more about sourcing check this webinar on Scenario-based sourcing.

4. Compare Supply Chain Scenarios with anyLogistix

Executives and management find the scenario comparison experiment in anyLogistix to be the best part.

Executives and management find the scenario comparison experiment in anyLogistix to be the best part.

Who am I to disagree with that?

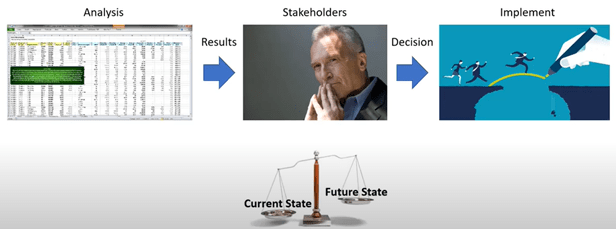

Bottom line is that trailblazing supply leaders must make important decision.

The scenario comparison experiment in anyLogistix allows organizations to compare their current “AS-IS” supply chains performance to the future “TO-BE” performance with one click.

The old way of business was to invest time and money into a project and then implement to see results 6-12 months later only to find out that it did not work as expected or work out at all.

With simulation you implement the change in a risk-free environment. anyLogistix will show you the results; from a P&L comparison to service level performance, risks, tradeoffs, and bottlenecks.

It’s like literally pressing fast forward on your supply chain and comparing the results of multiple scenarios.

This saves you time and money. Imagine having the tools and the time to compare strategies and choose the best one with the biggest return while maintaining your objectives. It is like reverse-engineering the results you want. Now imagine if your competitor had this capability.

Want to know how trailblazing supply chain leaders like you are using scenario comparison with anyLogistix, check this article and webinar on How To Compare Supply Chain Scenarios with AnyLogistix.

5. Capturing What Makes Your Supply Chain Unique with Extensions in anyLogistix

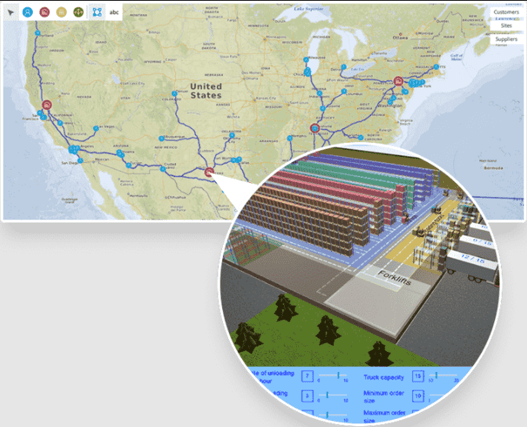

Your supply chain is unique. It has its own characteristics, and you need confidence that you can capture that in a model. Extensions are unique to ALX. They provide the ability to change the behavior of any point or policy in your supply chain.

When you work with anyLogistix, you will have the confidence that the tool can capture the DNA of your supply chain and what makes it unique. With anyLogistix extensions you can change any point in the supply chain like a DC, factory, supplier, customer, inventory, transportation, sourcing, etc.

This flexibility allows customers to go into the details or behind the scenes to capture what makes your supply chain unique. There is no other tool that allows an organization to design their point or policy like ALX.

Imagine being able to import the design of the Warehouse to evaluate capacity, the number of dock doors, employees, load/unload rates, and/or forklifts to prove that the design will perform well in the next 10 years with a business growth of 5% every year only to find that 7 dock doors is not enough and creates a bottleneck on year 8 during the high season.

All of these capabilities are included with an anyLogistix license. Check this site and webinar on how you can embed the inside 4 walls model into a Supply Chain.

Book a Call

If you’re using anyLogistix and want to see how you can apply any of the points discussed in this article book a call with us today. We’d love to hear about what you’re working on and guide you on how to apply anyLogistix to solve your business problem.

If you aren’t using anyLogistix, and you’d like to see if it can help you book a call here. We’ll schedule time to learn more about you and your supply chain and answer your questions around anyLogistix. When you have a model of your supply chain built with anyLogistix, you’ll feel like you can press fast forward on your business decisions, saving you years of refinement and errors, and not to mention millions of dollars. So, book a call here, and we look forward to meeting you soon.

About SimWell

At SimWell, we know you’re a trailblazing business leader, and it’s your job to make confident, informed decisions. The problem is you have a complex operation with infinite variables and interactions that just don’t fit on a pivot table. This leaves you utterly underwhelmed by the predictive tools at your disposal, and completely overwhelmed by the massive decisions looming.

We understand the all-consuming nature of big decisions, and the sleepless nights that surely follow. We know the pressure you’re feeling and we’re here to help. You need REAL answers based on the complexities of your operation. With cutting-edge simulation software from SimWell, you get just that.

We help you accurately predict the outcome of your decisions, giving back years of trial and error, saving you countless costs, and setting you free to be a trailblazing business leader. Press fast-forward on your big decisions with SimWell.