Supply chain risk analysis should consider all of the risks in your supply chain.

- How will a Coronavirus quarantine near a point in our supply chain impact operations?

- How will a ransomware attack on one of our facilities impact our supply chain?

- Will a tariff make it more profitable to move operations to a new country?

- How can a price hike be used to our advantage?

In every supply chain, an unpredictable villain is always waiting around the corner.

A natural disaster, a political change, a fast-spreading pandemic, a cyberattack, a strike, and various forms of disruptions create unplanned risks to a supply chain.

With the right approach to supply chain risk analysis, companies can minimize the impact of these disruptions.

Capturing Disruptions in Supply Chain Risk Analysis

The common disruptions to the supply chain have historical data to incorporate into their supply chain risk analysis and supply chain planning.

What makes disruptions like the Coronavirus different is that they don’t follow a pattern. Coronavirus is one type of disruption to the supply chain that has little historical data to follow. There is data about the spread of a disease, but not the factors that impact the supply chain – both upstream and downstream.

Due to a lack of historical data on these types of events, it is difficult to predict them with any level of accuracy. Therefore, most companies fail to plan for these disruptions.

When a low probability, high-impact event occurs companies are left with one option – react to the fast-changing environment in front of them. It’s never easy because every other company impacted by the disruption is reacting to the same event.

Even if you’re able to find a reactionary solution to mitigate the disruption, you’re most likely competing with your competition for that solution – whether you’re fighting for excess capacity in another facility or for raw materials from another supplier.

In the light of the coronavirus outbreak, quarantines are keeping workers from getting to factories and restricting where and how shipments can move from location to location.

Becoming Disruption Agnostic

You should plan for supply chain disruptions like the Coronavirus. If you’re unprepared your company will lose in the short term and have an unnecessarily long time to recover.

If you plan for disruptions, your company will minimize short-term losses and the time to recover from the event.

But, the underlying issue still remains – most companies do not have the historical data required to accurately plan for these unique disruptions.

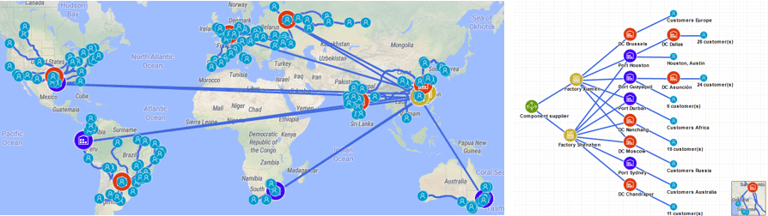

The answer is simple – do not plan for the event itself. Plan for the loss of an asset (node) in your supply chain without knowing the reason why. If your factory in Wuhan goes down for a week (a day, a few weeks, a few months) it does not matter if the cause is a Coronavirus outbreak or a strike.

It may be a pandemic, a natural disaster, a cyber-attack, or a spike in tariffs that require an alternative supply chain strategy.

If you become disruption agnostic and start planning for the loss of an asset in your supply chain, you’ll eliminate the need to know the likelihood that an event occurs and you’ll understand how to operate when the assets in your supply chain are lost.

How To Plan For The Loss of Assets With Supply Chain Risk Analysis

Supply chain optimization helps companies to find the optimal way to operate their supply chain to meet an objective. Typically they aim to maximize profits or minimize cost while meeting a specific service level. While optimization is key to improving your supply chain it falls short in risk analysis.

Optimization is like taking a snapshot of a supply chain to determine the optimal configuration for a point in time. It falls short for risk analysis because it does not include time, variability, or system interactions.

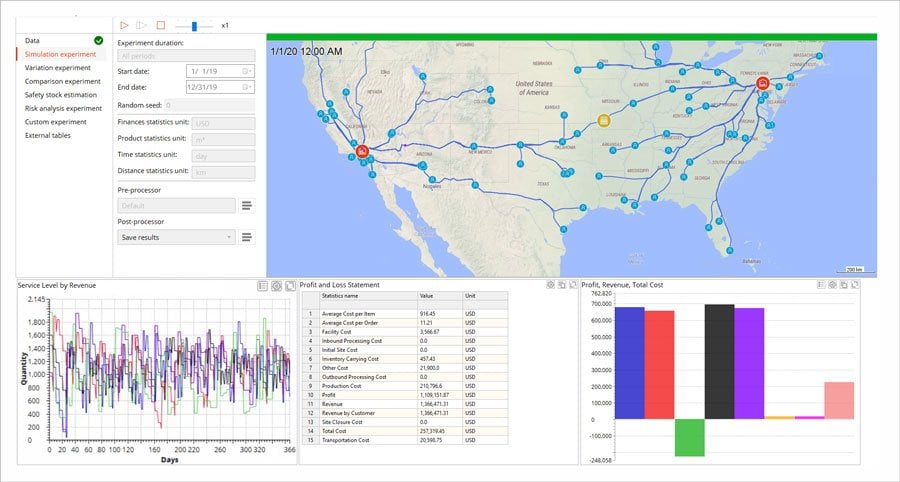

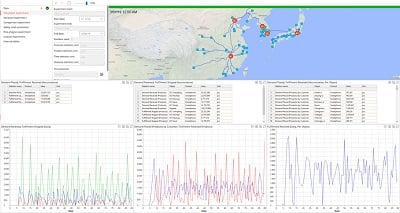

Simulation is another supply chain analytics technique that captures more information about the supply chain including time, interaction, and variability. By capturing all of the complexity of a supply chain in a simulation model, companies are able to replicate their supply chain in a virtual world and validate against performance in the real world.

A virtual representation of the supply chain is necessary for proper risk analysis because it allows you to test disruptions in a completely risk-free environment. You cannot shut down a real-world facility for two weeks just to understand how it will impact your supply chain, but you can turn it off in the simulation model.

If you’re interested in replicating your supply chain in a virtual environment, we’ve organized the step by step process that we use to build simulation models. You can access the free guide here.

How The Right Analytics Approach Will Make You More Competitive After a Disruption Like Coronavirus

Replicate Your Supply Chain in a Virtual Environment

When you capture the complexity of your supply chain in a simulation you are replicating it in a risk-free virtual environment. You can use this model for strategic and operational decisions. Simply import data from your real-world system and run the model.

Models built by SimWell will run thousands of iterations in seconds so you can compare every alternative quickly. Our customers that build supply chain models tell us this is the best tool they can bring to their supply chain war-room meetings. They used to identify scenarios to test and wait for weeks until their team could test each scenario in a spreadsheet. Now, they run them instantly in a simulation model so their leadership team can have conversations about what’s happening in each scenario.

See Your Supply Chain Operating On an Actual Map with Real Roads

Identify System Dependencies and Bottlenecks

System dependencies and bottlenecks lead to queuing, shutdowns, etc. When you run a model, you’ll see a queue or low utilization in your data and you’ll see it on a map. You’ll know exactly where a queue is happening and why so your team can plan alternatives to minimize that risk.

Improve Communication With Your Team and Suppliers

You know how it’s hard getting buy-in from each node in your supply chain because every node has different objectives? Visual models that show the risks and benefits to each node across a supply chain make it easier to communicate with each stakeholder. When you show the animation of your supply chain model you’ll improve buy-in and spend less time convincing your partners there’s a better way.

Identify and Quantify Unforeseen Risks In the Supply Chain

Your supply chain is a series of steps that happen over time. You can’t identify all of the risks in a real-world supply chain because you can’t fast forward to see all of the ways the supply chain can change. With simulation, you’ll run thousands of iterations of your supply chain in a matter of seconds. You’ll identify risks that you’ve never seen before and quantify them. Most importantly, you’ll be able to plan how you can manage around them to mitigate risk. anyLogistix makes supply chain risk analysis faster and easier so more companies can improve their operation.

Coordinated Inventory Policies to Truly Optimize Inventory

When you optimize inventory, you will know exactly how much inventory you will need to meet demand. Inventory optimization includes demand forecasting, inventory policy, and replenishment over time. anyLogistix is an innovative supply chain analytics tool that helps you to utilize simulation and optimization. Simulating inventory policies over time in anyLogistix means you can coordinate inventory policies across your supply chain and truly optimize inventory.

Understand How Policies Impact Service Level Over Time

Today companies are turning their focus to the supply chain to create differentiation. They know they can beat the competition if they can deliver products faster and cheaper (think Amazon Prime). With simulation, you can understand how policy changes and disruptions impact the supply chain over time.

Quantify and Manage The Bullwhip Effect

Small events can have a ripple effect on the supply chain. Simulation helps analysts to capture business processes and operations across multiple tiers so that you can quantify the bullwhip effect and manage it.

When you capture the complexity of your supply chain in a virtual environment you will be prepared for disruptions – no matter the cause.

anyLogistix to Replicate Your Supply Chain

anyLogistix is a software tool that helps companies to replicate their supply chain and analyze improvements in a risk-free environment. anyLogistix combines analytical optimization with powerful simulation technology, so you can analyze and innovate with confidence.

About Us

SimWell is the North American leader in simulation and optimization solutions. If you need help with supply chain design, or you need to find the right tools to do it yourself we can help.

It starts with a conversation. Send us a live chat, or click Start the Conversation in the top right. We want to learn about your supply chain challenges and see how we can help.