Introduction

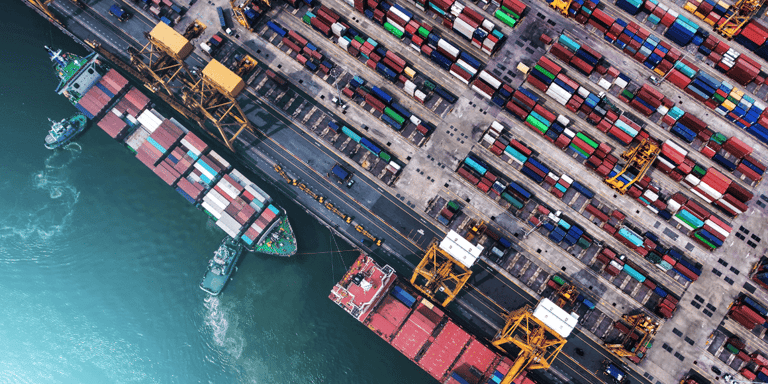

In today’s interconnected world, supply chains between the United States, Canada, and Mexico play a vital role in the North American economy. From vehicles to agricultural goods, trade across these borders is essential for businesses and consumers alike. However, tariffs and trade policy shifts introduce significant challenges, disrupting well-established supply chain networks.

The Trump administration’s push for tariffs under the guise of "America First" policies brought significant attention to US-Canada trade. Tariffs on Canadian aluminum and steel aimed to protect US industries but triggered retaliatory measures, sparking trade tensions. These actions revealed how even close trade partners can face disruptions due to shifting policies. The ripple effects of such tariffs on industries like automotive and manufacturing underscored the fragility and interconnectedness of supply chains.

In this blog, we’ll explore how tariffs like these impact supply chains and how businesses can adapt using optimization and simulation.

1. How Do Tariffs Impact Supply Chains?

Tariffs can ripple through supply chains in profound ways, creating disruptions at multiple levels. Here’s how:

- Increased Costs: Tariffs act as a tax on imported goods, raising the cost of raw materials, components, or finished products. This impacts pricing, profit margins, and overall competitiveness.

- Sourcing Challenges: Businesses often rely on suppliers from tariff-imposed regions like Canada or Mexico. Tariffs may force a shift to alternative suppliers, which can increase lead times or reduce quality.

- Customs Delays: Higher regulatory scrutiny at borders due to tariff policies can slow down shipments, impacting inventory levels and customer satisfaction.

- Double Impact on Mexican Trade: Mexico’s role as a gateway for goods from China means that tariffs targeting Chinese manufacturing can compound costs for North American companies relying on Mexican trade routes, amplifying supply chain disruptions.

- Production Adjustments: Industries like automotive or electronics, which depend on integrated supply chains spanning multiple countries, must reorganize production to offset new costs. For example, a tariff on auto parts imported from Mexico increases the cost of producing vehicles in the US, potentially requiring manufacturers to source parts elsewhere or pass higher costs to consumers.

2. The Importance of US-Canada-Mexico Trade

Trade within North America is vast and complex, governed by the USMCA. Consider these key exports:

- Canada to the US: Vehicles, crude oil, machinery, lumber, aluminum.

- Mexico to the US: Vehicles, auto parts, electronics, machinery, agricultural products.

These goods form the backbone of critical industries such as automotive, energy, and technology. Disruptions to these flows due to tariffs can have far-reaching consequences.

3. Common Supply Chain Pain Points

Tariffs introduce challenges that require immediate attention. Here are three common pain points businesses face and how to address them:

Pain 1: How should I change the network to keep serving customers being even more profitable than before the tariff?

- Businesses need strategies to adjust their supply chain networks while maintaining service levels and minimizing costs.

Pain 2: How can I optimize the network with new constraints?

- Tariffs introduce constraints such as higher costs and potential delays. Optimization helps navigate these challenges to ensure efficiency.

Pain 3: How can I quickly pivot how changes like tariffs, port strikes, or hurricanes impact the supply chain?

- Real-time modeling and simulation provide insights into the immediate and long-term effects of such disruptions, enabling quick, informed decisions.

4. Strategic Roles of Canada and Mexico

Canada’s Strategic Role

Canada is a linchpin in North American supply chains due to its:

- Energy and Natural Resources: A leading supplier of crude oil, natural gas, and minerals critical for industrial production.

- High-Quality Manufacturing: Specialized industries like aerospace and automotive parts, which rely on advanced production capabilities.

- Stable Trade Environment: Long-standing trade agreements and infrastructure support efficient cross-border operations.

Mexico’s Strategic Role

Mexico plays an equally critical role, offering:

- Cost Efficiency: Competitive labor costs make it a manufacturing hub.

- Proximity: Close geographical ties to the US reduce transportation costs.

- Gateway for Global Trade: Mexico serves as a primary entry point for goods manufactured in China and other global markets, complicating trade dynamics further when tariffs are applied.

- Sector Specialization: Expertise in automotive, electronics, and agricultural exports supports diverse supply chain needs.

Both countries are indispensable for creating resilient and cost-effective supply chains for businesses operating across North America.

5. The Power of Optimization and Simulation

The Solution: Visualize the Network

Imagine a dynamic model combined with an intuitive dashboard showing:

- Current supply chain flows, costs, and service levels.

- Scenarios simulating tariff impacts or other disruptions like port strikes or weather events.

- Optimized adjustments to sourcing, routing, and inventory.

How Optimization and Simulation Address Pain Points

- Inventory Scenarios: Analyze the trade-offs between holding more safety stock to mitigate risks and minimizing inventory costs.

- Sourcing Strategies: Identify alternative suppliers in Canada, Mexico, or other regions with lower total landed costs.

- Impact Forecasting: Quickly assess the ripple effects of tariffs or external shocks on the entire network and prepare actionable responses.

The Reward

The outputs of these tools help businesses:

- Make Better Decisions: Gain clarity on cost-effective changes to maintain customer service levels.

- Build Resilience: Prepare for various disruptions, from tariffs to natural disasters.

- Drive Efficiency: Unlock savings and operational improvements despite external constraints.

6. Partner with Experts

SimWell Consulting and Technologies is a global company specializing simulation, optimization, and digital twin technology. Our core mission is to unlock simulation at scale. We empower leaders and operators to maximize their current resources, optimize their operations, and elevate their performance with simulation. We build models of our customers operation, test scenarios, and predict how it will perform in a risk-free environment.

With SimWell as your partner, your team will have the tools to make confident decisions, optimize your process, and press fast forward on your business.

Conclusion

Tariffs between the US, Canada, and Mexico are reshaping supply chains, but businesses that act strategically can turn challenges into opportunities. Contact us today to explore how we can optimize your supply chain for the future.