As the director of a manufacturing facility, you feel the weight of responsibility and have many things vying for your attention. Despite this, you love the impact you can have by pointing your teams in the right direction.

The manufacturing facility comes across two scenarios: longer periods of normal levels of demand and shorter periods of high demand. During these two scenarios, you know to apply different strategies.

- During normal levels of demand, the strategy is "prioritize quality."

- During high demand, the strategy is "prioritize throughput."

Demand seems to be picking up. When do you change strategy? There are many variables, and you often must rely on intuition your team has built up over many years.

- If you change to "prioritize throughput" too soon, you take the unnecessary risk of producing defective products that will need to be reworked or scrapped.

- If you change to "prioritize throughput" too late, you risk late delivery of your products, hurting your brand and bottom line.

The consultants at SimWell have worked in a variety of industries and know the difficult decisions faced by manufacturing leaders when complexity is high. It is often unclear which strategy to take, despite the abundance of data.

SimWell's AI experts can help you develop an autonomous AI solution that removes ambiguity from your strategy-selection process.

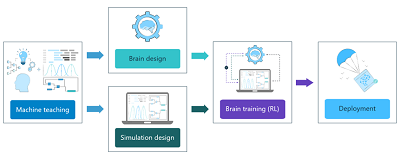

You will work closely with SimWell's consultants, who will build a simulation of your production line. It will include all the information that you receive as inputs to your current strategy-selection process. One of SimWell's AI experts will use machine teaching to teach an autonomous AI agent the production concepts specific to your facility (e.g., what constitutes "normal demand" and "high demand"). After training for decades of simulated time on the simulation of your production line, the AI agent will use its learned experience to help you know when to employ each strategy, (e.g., "prioritize quality" and "prioritize throughput"). The AI can be connected to your line's production control system and PLCs to enact these strategy changes in real-time during 24-hour operations.

Are your production strategies different than "prioritize quality" and "prioritize throughput?" Contact one of our directors of simulation today. Talk us through the problem you are facing, and we will work with you to develop a solution.

You can direct your efforts towards higher pursuits with your mind free from the distracting tactical decision of which production strategy to employ.

- "How do we phase expansion of the plant?"

- "How do we incorporate new products without excessive disruption?"

Don't let your strategic goals fall behind the tactical day-to-day. Having to focus on the near term takes your eyes off the horizon.

SimWell's autonomous AI solutions will select the best strategy for your production line, enabling you to leverage your hard-earned experience on problems only you can solve.