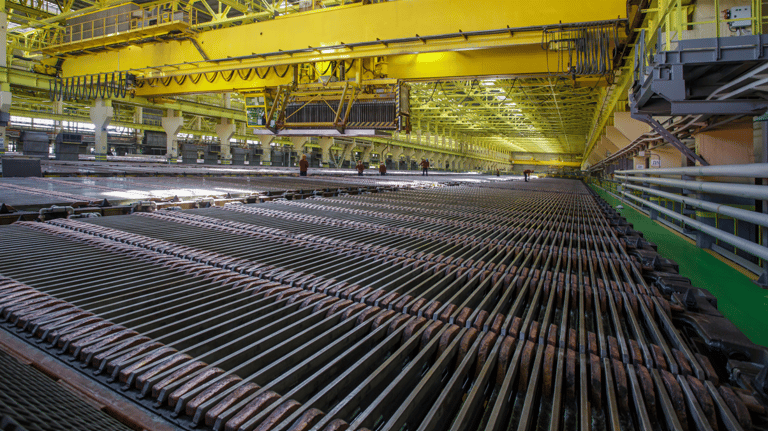

Moving bulk material by rail is a unique and complicated challenge. While the ultimate goal may sound simple and straightforward, the systems used to oversee this process are usually quite complex because it requires the integration of independent teams.

Transporting material from its source to a client as quickly and efficiently as possible may sound simple enough, right? Well, not quite. As part of the mining supply chain, you’re required to move materials quickly without ever turning into a bottleneck. Now that you understand the overall goal, let’s take a look at the type of systems that these logistics teams are working with.

The Challenge Part 1

Complex Systems in fast-changing environments

The challenge of integrated planning starts with all the constraints that a rail logistics team must consider and adapt to, such as:

- The trains are often aggregated from several blocks and come from different sources that must be synchronized on the same network.

- Unidirectional rail segments are very rare, making it necessary to carefully plan the position of sidings to allow train meets. Timing these meets is always a difficult task.

- The sources may not have the ability to load and deliver the cars on time.

- Some rail segments are operated by third parties that typically only give wide timeframes for pick-up and drop-off at different locations.

- Rail equipment must be maintained regularly (load-outs, locomotives, dumpers, ship loaders, sheds, rails, sidings, etc.). If not, the risk of unplanned maintenance events will increase every day.

- Worker attendance issues—such as changes in availability, absenteeism, conductors trading shifts, training seminars, and more—can easily disrupt operations and schedules.

- Car fleet management and shortages.

- Weather-related and meteorological events that can cause delays because material cannot be loaded during rain, heavy snow, and other severe weather.

As with all supply chains, the entire integrated planning operation must be run as tightly as possible. Any unplanned activity that occurs during this process can lead to a series of events that can take hours, days, or weeks to stabilize.

The control center experiences disruptions, delays, and unexpected crises on a regular basis. Ensuring that the system runs as smoothly as possible can be a monumental task for a logistics team, which must:

- Aggregate all available strategic and operational system information, and continuously establish the best possible forward-thinking long-term plan.

- Control the plan execution and react quickly to any change or deviation in real-time, day-by-day and minute-by-minute.

- Crunch data and formulate new plans continuously and then execute, oversee, and control the plan.

The challenges faced by a logistics team bring to mind a common military adage: “No plan ever survives first contact with the enemy.”[1]

This means that it’s important to plan continuously, but that the plan can go out the window just as quickly as it was developed. As Dwight D. Eisenhower said, “Plans are worthless, but planning is everything.”[2]

Everything relies on the quality of the data or information that’s available—along with the ability of the team to process it quickly, efficiently, and correctly.

The Challenge Part 2

The Uniqueness of Each Rail Network Operations and a Team Under Pressure

This is a fast-moving network of many pieces that have constantly-evolving problems, and these problems require speedy solutions to keep the system optimized and running efficiently.

Surely, there must be some effective integrated planning solutions that can achieve this? Well, yes and no. Here’s why finding the right set of tools can be difficult:

- No two control centers are exactly the same. These operational centers are the brains behind very unique systems that operate in unique environments with unique components. This complexity scales exponentially when taking the number of components managed into account (sources, clients, product types, terminals, rail providers, etc.).

- When compared to space mission operation centers (where the applicable constraints never change), rail logistic operation constraints change every single day.

- Since rail logistics is an older industry, it’s often run using numerous internal tools, spreadsheets, databases, emails, and phone calls, with varying levels of experience in streamlining.

Because each of those systems is so complex, there is no one size fits all solution that could automate this work for all these teams.

To recap:

- A rail logistics team is continuously in crisis mode.

- This team is responsible for running a sensitive, complex, unique system made up of hundreds of components.

- The team must manage large amounts of data from informal sources, share it with peers, and identify the next best action to take as optimally and quickly as possible.

Maybe this sounds a little too familiar? No wonder rail logistics professionals require such high-tech control rooms! This isn’t the type of team that can simply use an outdated, one-dimensional software solution that may make their jobs easier in five or 10 years. They need help now.

This is where the SimWell team’s incremental approach comes into play.

The Solution

An Integrated Planning Control Room for the Value Chain

This approach allows for innovation without disruption and incrementally builds integration, prediction, and optimization solutions to support the logistics team.

First, by working with future users, we’ve identified the fundamental building blocks that ensure more efficient operations for the earliest deliverable product concept, which involves:

- The simulation of short-term dispatching scenarios, which allows the railway and its associated operations to get preliminary results involving the processes of production, shipping, maintenance, and resource management.

To achieve this with minimal operational disruptions, SimWell proposes a solution that focuses on building the most critical and urgent sections of a customer's operations first. We’ll also implement simplified versions of other services to ensure end-to-end visibility of each process.

Here's a summary of the approach and solution we provide:

- Prioritize building critical and urgent sections for end-to-end visibility.

- Streamline real-time system information and simplify operations.

- Apply iterative development and modular thinking—the SimWell Agile methodology.

- Continuously work toward a fully integrated Digital Twin of the complete system.

The Results

Leveraging this approach, SimWell provides a Digital Twin solution that delivers immediate value and sets the foundation for future scaling. This solution was developed by prioritizing the most critical and urgent operations and then gradually adding sophistication as needed.

This results in increased system-level throughput and a faster return on investment that can financially support its own future vision without breaking anything.

Typical rail logistics projects resulted in the ability to simulate scenarios within seconds, generating valuable new insights and results using existing data. The implementation of our tools leads to happy customers, future phases, and projects that allow us to implement a larger-scale solution with a wider scope of operations.

We also have the ability to progressively integrate optimization and AI technologies to make the control center operator’s job less stressful, one step at a time.

The SimWell Approach Can Apply to All Sectors

While this article focused specifically on rail transportation, the same ideas and approaches can be applied to other industries such as manufacturing, scheduling, mining, healthcare, supply chain, and more. In fact, virtually every field struggles with effectively managing an infinite amount of data in formal and informal sources, staying afloat in a fast-paced environment, handling the difficulties of unexpected emergencies, fear of risky monolithic technological implementation, facing the challenges of demonstrating ROI to unlock the required fundings, and more.

While the similarities may be obvious, how can a solution designed for a large team in a control room apply to your operations? At SimWell, we understand that every operations manager or decision-maker would benefit from visualizing their toolset as a control room, even if it’s not a physical room that contains dozens of monitors.

By adopting this way of thinking, the path forward becomes clearer, resulting in better insights for decision-makers. This allows them to make the best possible decisions at all times by offering:

- Visibility and transparency in real-time through the harnessing and presentation of all important live information in integrated dashboards.

- Predictive and prescriptive analytics gathered by the development of robust forecasting tools in a risk-free experimentation environment.

Interested in learning more? Book a demo to see how SimWell can help you increase insights to make more calculated decisions and improve your systems and operations.

Footnotes

2 1958, Public Papers of the Presidents of the United States, Dwight D. Eisenhower, 1957, Containing the Public Messages, Speeches, and Statements of the President, Remarks at the National Defense Executive Reserve Conference