Supply chain network optimization grabs attention when leadership talks strategic planning, supporting growth, adding new product lines, and so on. Supply chain network optimization solves a very complex problem for companies, and the problem is that most supply chains have been developed with a series of decisions made over time.

The Trigger For SC Optimization

The problem isn’t in those decisions themselves. The problem is that as time goes on, the supply chain grows and becomes increasingly complex.

When you increase the size and complexity of a supply chain, you also increase the impact of inefficiency. Inefficiencies begin to have large, ripple effects on costs, service levels, and overall ability to manage the supply chain. The good news is that we can solve this complex problem.

The aim of supply chain network optimization is to understand how the supply chain works today, and identify alternatives that support changes in a business.

Why Supply Chain Network Optimization?

Traditionally, supply chain network optimization focused on minimizing cost and maximizing profit.

Of course, that’s still a focus for every successful company. What’s different today is that businesses are differentiating themselves by offering customers bold service guarantees.

Amazon was a trailblazer here with Prime 2 Day Shipping that launched in 2005. Walmart didn’t step up to the plate until 2017, but the war is on now.

Companies are moving from 2 day shipping to next day pickup to same day delivery, and sc network optimization objectives are weighing heavily towards meeting minimum service levels.

The service war is just heating up. Last mile delivery is the next wave of service disruption as companies find ways to deliver from a hub to a final delivery destination within a day, if not hours. Companies like DHL, UPS, and Amazon are testing drone deliveries around the world.

Once a company sets a goal like 2 day delivery, optimization is one of the tools that helps them create the supply chain strategy and infrastructure to achieve the goal.

Always Make The Right Decision

Supply chain optimization is about systems thinking, and make the right decision for the system to work as whole.

Optimization allows companies to make the right decision when they are considering supply chain changes that impact the system.

When a company is trying to decide how to build a supply chain that meets an optimal objective of maximizing profit while meeting a 2 day delivery time frame, they need to consider plant locations, distribution center locations, capacity for their facilities, what products to produce or buy and from where, inventory requirements, and customer service levels.

Supply chain network optimization is used when making a decision in any of these areas to ensure the focus is on improving the system.

When Do You Need Supply Chain Network Optimization

The simple answer: When the supply chain is changing…or preferably before the supply chain changes.

The long answer:

- Strategic planning – I once worked with a billion dollar supply chain that used excel for supply chain network planning which took multiple people weeks every quarter. It was worth it, because it was the backbone of their supply chain. Once we introduced what simulation and optimization could do for the team, it allowed them to have the same strategic conversations around a board room table in a couple hours, instead of going back and forth via email for a few months.

- Carbon footprint reduction – The markets have spoken. Going green isn’t just good for the environment, it’s good for the top line too. Supply chain network optimization allows companies to optimize on things like their carbon footprint. Companies that take bold stances on the environment have a lot of work to do in their supply chain.

- Growth – Growth is great, but it creates new problems. Especially in the supply chain. When you know what you’ve done before isn’t going to get you where you’re going, it’s time to consider new approaches to supply chain management.

- New Product Lines – Adding new product lines can change the fundamentals of your supply chain, and often require a new approach to ensure there’s no impact on existing business and that the new products can be delivered within acceptable terms.

- Other areas where supply chain network optimization supports the business includes changes in the customer base, expansions, acquisitions, sourcing, new markets, mergers, etc.

Supply Chain Network Optimization Ought To Be Within Reach for Every Company

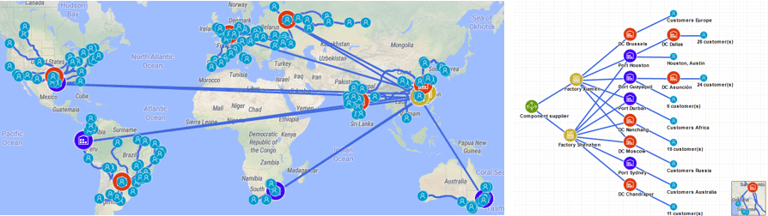

At SimWell, we believe that optimization ought to be within reach for every company. Tools like AnyLogistix make that possible by combining the best in class simulation engine and best in class optimization engine with a simple interface that allows anyone to design, optimize, and simulate their supply chain. Combine network optimization, greenfield analysis (GFA), risk analysis, supply chain master planning, and more with AnyLogistix.

You can do supply chain network optimization yourself, and SimWell provides the tools and support to make you successful. If you’re too busy, we are a supply chain consulting company with experts on staff that are able to do it for you.

About Us

SimWell is the North American leader in simulation and optimization solutions. If you need help with supply chain network optimization, or you need to find the right tools to do it yourself we can help.

It starts with a conversation. Send us a live chat, or click Start the Conversation in the top right. We want to learn about your supply chain challenges, and see how we can help.