By Alexandre Ouellet, President, SimWell

NOTE: The original article was originally written by SimWell and published by Rockwell in the Arena Newsletter. Read the updated version now.

Simulation can offer many benefits to mines and the ore processing plants they work with. Simulation is used by this type of plant to address important business considerations, such as:

- Large investments.

- Strategic decisions that can have a major impact on project profitability.

- The understanding of interdependent and complex systems, which may include:

- Equipment availability (failures, preventive maintenance, redundancy).

- Operator availability (limited HR, schedules, operator specialties, absenteeism).

- Ore properties (type of ore, grade of ore).

- Operation times.

- Factors related to weather.

- Wait times at key resources.

- Stockpiles and tank limitations.

- Headings availability at a given time.

- Traffic in the mine.

- Data variability, including:

Transporting Ore with Trucks—Discrete System

A mine is a system that can be accurately modeled using discrete event simulation. For example, ore transport operations may appear similar to the following sequence:

- The truck moves toward the shovel.

- The truck waits to get loaded.

- The truck gets loaded.

- The truck moves towards the crusher.

- The truck waits for its turn to unload.

- The truck unloads in the crusher.

- The truck goes back to the shovel.

Although this example is an oversimplification, these operations represent a typical discrete system, in which entities (trucks) go through a process and seize-delay-release resources (shovels and dump hopper pockets).

Ore Processing – Continuous System

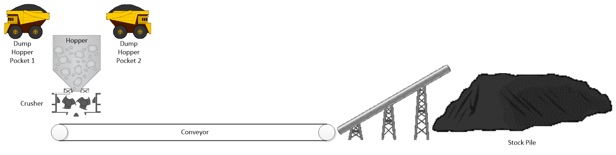

Mining simulation projects aren’t limited to just the mining operations themselves. It’s also important to accurately model ore processing plant operations. The processing plant is more of a continuous system than a discrete system. For the rest of this article, we’ll assume the following basic process:

Strategies to Model Ore Processing Plants and Continuous Systems

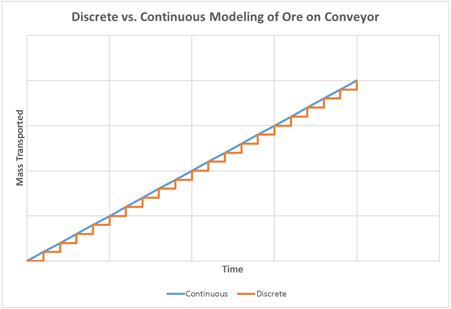

An ore processing plant is not discrete, but continuous. Using Arena simulation software, the flow of ore on a conveyor can be represented in a continuous manner. It’s also possible to discretize the flow. Here is a comparative analysis of the three methods:

Discrete Mass

With this method, the continuous flow of ore on the conveyor belt is represented using discrete entities, whereas the entity is equal to a predefined unit of mass of ore (for example: one entity equals one ton).

As shown in the graphs below, the smaller the reference mass is, the closer the model will get to a continuous behavior. The higher the mass, the less precise the simulation. It may be helpful to choose the smallest possible reference unit in order to obtain the most precise results.

However, the smaller the reference mass is, the higher the number of unique events. Hence, the model will take longer to execute. A slow model means more tedious verification and validation work—and the cost of running several scenarios increases. This may force the analyst to reduce the number of scenarios to run or to increase the duration of the project. That’s why it’s important to choose a reference unit that compromises between precision and model performance. That unit depends on the total volume of mass moved within the simulated timeframe, the required precision of the model, and the type of decision that needs to be made.

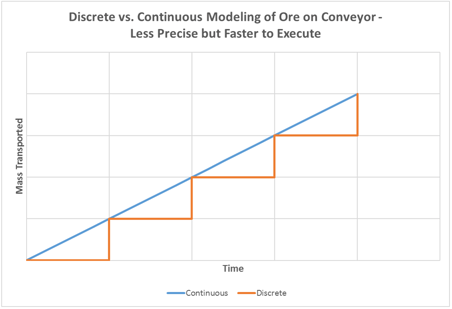

Discrete Time

This method is similar to the previous one. In an ore processing plant, the flow of ore is represented in a discrete manner, whereas an entity corresponds to the mass transferred within a certain time (for example: one entity equals the mass transferred during one minute). Analogically, the shorter the chosen time unit is, the closer you get to running a continuous model. Of course, a longer time unit means lower precision. The shorter the time unit is, the costlier the simulation will be in terms of computer execution time.

Continuous

It is possible to model the transport of ore on conveyors in a continuous manner using Arena and the tools provided in the flow process template. If one models the hopper-crusher-conveyor-stockpile sequence shown in the photo above, the hopper and stockpile are represented by tanks.

Each dump hopper pocket is represented as a regulator. When the truck arrives and begins dumping into the hopper, it seizes a regulator, then flows in the tank until the quantity of ore in the truck is emptied. Finally, it releases the regulator. The conveyor is represented as a flow between an output regulator of the hopper and an input regulator of the stockpile. Below is a picture of the Arena logic. Please contact SimWell if you’d like a copy of this model.

The crusher does not need to be represented by a piece of equipment because it’s in series with the hopper and it doesn’t have accumulation. If the crusher is in maintenance, then the flow rate out of the hopper can simply be regulated to zero. There isn’t always accumulation before every piece of equipment within a process. If one needs to model a process that adds or removes mass, then it can be modeled as a tank. In this scenario, there is no accumulation and the inflow will always be maintained equal to the outflow.

The advantages of using the flow process template are:

- No loss of precision due to discretization.

- Model execution speed.

These advantages can be costly, depending on the application. Between the use of discrete and continuous methods, we can quickly lose the concept of entity. The entity can be crucial if we must track attributes of the ore precisely (for example, ore grade). We must also assume that the length of the conveyor is negligible in our system. The assumption is usually acceptable with continuous conveyors because the sequence of events at the end of the conveyor is the same as at the start of the conveyor. This is also the case for plants that operate 24/7 and plants where conveyors don’t get emptied at the end of a shift.

Discrete vs Continuous Methods

Choosing a modeling method depends on the system that needs to be modeled. If we track the attributes of the ore precisely, you may want to opt for discrete methods. Other factors could also lead us to choose a discrete method. For example, repairing a conveyor after a failure might depend on the quantity of ore traveling on it.

However, it may not be necessary to track the attributes of the ore. If the level of precision required for the ore characteristics is less important than the precision required for the mass, it’s advised to use tools from the flow process template because they improve the model execution time.

Learning More About the Flow Process Template

Interested in learning more about the flow process template? We’re here to help. Learn More about Simulation in Ore Processing

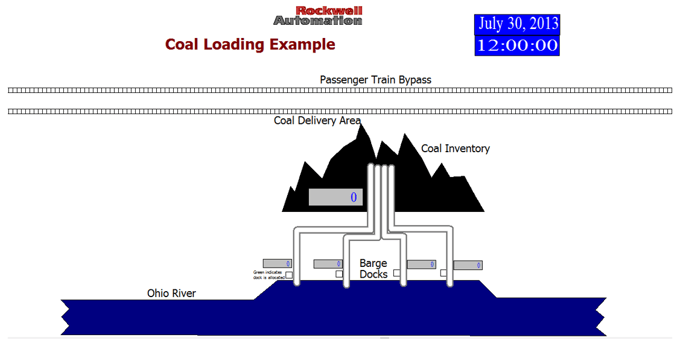

If you’d like to learn more, check out the “coal loading” example that comes with Arena software. You can find that example in the following path on your computer: C:\Users\Public\Documents\Rockwell Software\Arena\Examples\FlowProcess

This model created by Rockwell demonstrates in a simple context the complete range of tools from the Flow Process Template.

Free Arena Simulation Model - Flow Process Template

This custom-built sample model demonstrates the use of the arena flow process template to simulate ore processing plants. The model can be run and modified using the free evaluation version of Arena.

Click here to download your free Arena model.