In times of uncertainty the unknown is scary. For supply chain leaders, the focus goes from making optimal decisions to making the best of what's in front of you.

It’s difficult (if not impossible) to forecast when and where events such as COVID-19 (coronavirus) will happen, but we can predict that they will happen. We can also predict what comes afterward, the consequences.

This is the premise of building a resilient supply chain.

It does not require us to know exactly what/when something will happen, but we do need to identify critical nodes (Suppliers, Factories, DC's, and Customers) in the supply chain and make a plan to respond to such an event.

How can a volatile event such as the pandemic impact global economies?

What we know today is that human behavior after such an event is even harder to predict. In an event like this pandemic, people have a real and serious impact on global economies. This will, of course impact supply chains.

The intensity of people's reactions is often unknown.

The reaction of the world in face of the pandemic today is a stark lesson that we need to learn how we can better prepare for unknown volatile situations.

These situations are learning opportunities for us, so reflection, education ,and preparation will be essential to reduce the financial impact to our organizations and the ability of our supply chains to service customers.

What types of events can impact our supply chain?

There are many events that can change the network design of our supply chain: transportation driver rules, gas/oil prices, tariff changes, sourcing changes, a strike, border times, flooding, losing a supplier, earthquake, virus, cyber attack, high demand, low demand, overstock, under stock, limited resources, and materials, etc.

Some of these we can predict because we have historical data about the likelihood and magnitude, but others we can't predict. That's why a key to building a resilient supply chain is understanding how a supply chain will react to any event.

How can we recognize if a supply chain is fragile?

There are commonalities between fragile supply chains. Here's a few of them:

- There is no transparency throughout your supply chain to react tactically and optimally

- Supply chain is managed manually, making changes difficult

- Inventory levels are sub-optimal leaving no room for supply shortages or volatile events

- There are no multiple supply sources providing and/or factories producing the product or all sources are potentially in the same region

We can recognize if a supply chain is fragile through analysis.

We recommend using simulation to replicate your supply chain in a digital environment, and then turning off every node 1 by 1.

When you do this, you'll identify the most critical nodes in the supply chain, and be able to test your response plans.

Should we prepare and if so how?

The one certainty is that these events will become more frequent, and for a business to thrive in today’s world, it will require preparation in the following areas:

- Pre-event: Risk analysis, How prone are you currently to be affected by these volatile events?

- Pre-event: Strategically going forward, how will you operate to reduce some of that risk?.

- Forecasted Event: Strategically, how can you prepare in anticipation (if applicable)?.

- During Event: Tactically, how will you react when the event happens. At this point, the tactical approach on how to solve your problem will require an efficient and effective decision-making process, including preparation and organization of:

- People – Educating, Managing change, Action and Communication Plan

- Data – Having clean and ready to use data to develop scenarios

- Software/System – Running simulation models to assess risk and curve the risk as much as possible, if service level or demand is not possible to meet.

- Post Event: A postmortem to challenge and improve future processes or breakdowns that occurred

As we all know, risk analysis is becoming the key to preparation. It helps us to identify risks and make strategic decisions to build resiliency, and it helps us to create tactically plans so that we can react quickly when volatile events occur.

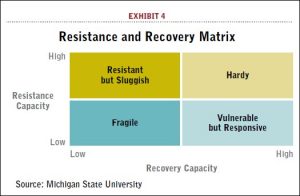

See the matrix on resistance and recovery.

Is there software available to support risk analysis?

ALX (anyLogistix), is a network design tool that helps companies to quickly replicate their supply chain in a digital environment. ALX then allows organizations to analyze scenarios in a risk-free environment.

One of the methods available in ALX is simulation. With simulation, the organization can perform a risk assessment of any supply chain. They can shut off nodes in the supply chain one by one to understand how each node impacts the overall supply chain, and identify previously unknown risks and critical nodes.

ALX helps companies to evaluate how their supply chain will perform. A variation experiment can also be performed to complete a stress test of the supply chain.

All things considered, the performance and behavior of your supply chain will be able to show the impacts, trade-offs, and risks in the supply chain.

How Can ALX Help You Build Supply Chain Resiliency?

- You can replicate your supply chain in a digital environment

- You can create events to understand how your network responds

- Use and experiment with different Sourcing Policies (Fixed, Dynamic or Multiple sources) to be more versatile

- Turn off every node in the supply chain to identify unknown risks and critical nodes

- Create a robust safety stock estimation to be more resistant, while optimizing your profit

If you want to see how anyLogistix helps to replicate your supply chain in a digital environment and perform risk analysis, check out this video.

About Us

SimWell is the distribution partner for anyLogistix in North America and a leader in simulation and optimization solutions. If you need help with supply chain risk analysis, or you need to find the right tools to do it yourself we can help.

It starts with a conversation. Send us a live chat, or click Start the Conversation in the top right. We want to learn about your supply chain challenges and see how we can help.