The COVID-19 pandemic dramatically highlighted the importance of maintaining a robust supply chain. While it may be impossible for businesses to predict every potential disruption or shortage, developing a plan of action during times of economic uncertainty can make all the difference.

What is Supply Chain Risk Management?

According to the Association For Supply Chain Management Dictionary, supply chain risk management is the “identification, assessment, and prioritization of risks, followed by coordinated and economical application of resources to minimize, monitor, and control the probability and impact of unfortunate events to maximize the realization of opportunities.”

Supply chain risk management also involves the development of strategies to fight potential supply chain threats, whether caused by the supplier, the supplies, or the supply chain itself: initial production, packaging, handling, storage, transport, mission operation, and disposal.

What Type of Risks Can Impact the Supply Chain?

Supply chain risks are typically caused by internal or external factors. Internal factors may include issues related to process contingency, process mitigation, and control. External factors typically include variables such as consumer demand, environmental conditions, and supply chain shortages.

According to Moody’s Analytics, there are many factors that can negatively impact supply chains, including:

- Poor supplier performance: This is often considered the most important risk and should be prioritized by businesses.

- Poor demand planning: Forecasting demand has become more complex. To keep up with consumer demand, businesses are required to purchase more than what they need. This can cause problems as many companies are unsure of the exact quantities of certain products that they may need.

- Inflation: Whether inflation takes place on a global or national scale, the rising prices of goods and services can make it difficult for companies to correctly manage and predict cash flow.

- Labor shortages: A lack of trained employees can indirectly result in supply chain risks because a lack of money and resources may prevent businesses from developing products or offering services on a specific timeline.

- Natural disasters: Weather-related events such as earthquakes, flooding, or severe storms can cause damage to businesses in impacted regions, hindering supply chain flow.

- Cyberattacks: A growing number of cybercriminals are targeting the logistics sector, leading to massive disruptions on both a national and global scale.

How Can Businesses Manage Supply Chain Risk?

Ongoing, integrated supply chain risk planning can help identify potential shortages or issues and plan accordingly. Additionally, investing in supply chain visibility using simulation, increasing the monitoring of vulnerability drivers, and automating vulnerable processes can dramatically reduce supply chain issues.

Using advanced analytics also allows businesses to observe potential supply chain issues in a risk-free virtual environment. Understanding the complexity of your supply chain through simulation models allows you to make better strategic and operational decisions. Here are just a few advantages of using analytics to improve your supply chain:

Boost Collaboration With Your Team and Suppliers

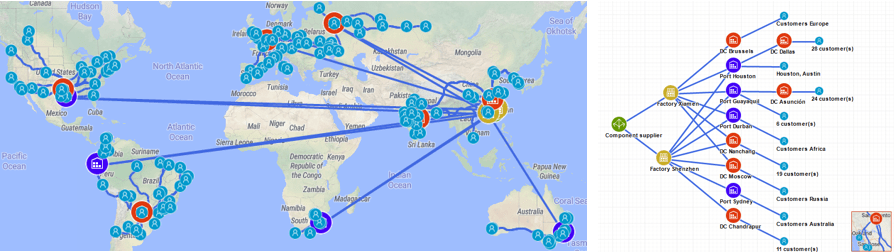

Visual models can identify any risks and benefits across a supply chain, making it easier to communicate with your team members and suppliers.

Identify and Quantify Unforeseen Risks In the Supply Chain

Using simulation models and the right analytics, businesses have the ability to observe thousands of different versions of their supply chain. This helps identify unforeseen risks. End-to-end supply chain planning tool anyLogistix also makes supply chain risk analysis faster and easier because it can be used to manage network optimization, inventory optimization, risks analysis, master planning, and more.

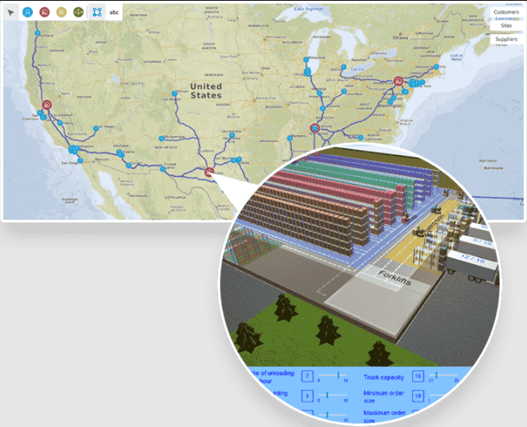

Optimize Inventory

Inventory optimization involves demand forecasting, inventory policy, and replenishment over time. Simulating these processes using anyLogistix allows you to coordinate effective inventory policies across your supply chain.

Increase Your Company’s Supply Chain Resilience

SimWell helps companies solve their business challenges fast in a risk-free setting. We build simulation models of business operations such as supply chains and warehousing. This allows managers to test changes before making large investments. SimWell helps organizations like yours to improve the inventory optimization process. Interested in learning more? Let’s talk!