In a landscape where disruptions are the norm rather than the exception, optimizing supply chain networks leads to manufacturing success. Businesses are striving to enhance efficiency, reduce costs, and bolster resilience, encountering challenges in supply chain management along the way. Fortunately, innovative technologies pave the way for operational advancements that can transform the way businesses operate. Discover how scenario planning and simulation can support supply chain network optimization.

The Complexities of Supply Chain Network Optimization

Supply chain network optimization entails an intricate balance of designing and managing the flow of goods, information, and finances across interconnected nodes. Amidst global uncertainties, businesses face conflicting objectives ranging from cost minimization to service level maximization and risk mitigation.

Navigating Different Approaches

To tackle the complexities of supply chain network optimization, businesses like yours can leverage a variety of approaches. Each is suited to different scenarios and objectives, so your chosen methods will vary based on what you wish to optimize.

1. Mathematical Optimization Models

Mathematical optimization models, such as linear programming and mixed-integer programming, offer a rigorous framework for decision-making. By formulating the supply chain problem as a mathematical equation, you can identify optimal solutions to complex logistical challenges. These models excel in scenarios where precise solutions are necessary, such as when determining optimal production quantities or transportation routes.

2. Heuristic and Metaheuristic Algorithms

In situations where finding an exact solution is computationally infeasible, heuristic and metaheuristic algorithms provide viable alternatives. These algorithms, including genetic algorithms and simulated annealing, employ iterative processes to converge toward near-optimal solutions within reasonable time frames. While sacrificing optimality for computational efficiency, heuristic approaches are especially invaluable for tackling large-scale supply chain optimization problems.

3. Simulation-Based Optimization

Simulation-based optimization combines the power of mathematical models with the flexibility of simulation techniques. By simulating various scenarios and evaluating their performance against predefined objectives, you can identify robust solutions that account for uncertainty and variability in the supply chain. This approach is effective in environments characterized by high complexity and stochasticity, such as production scheduling and inventory management.

4. Network Design Optimization

Network design optimization focuses on the strategic configuration of supply chain networks to align with business objectives. By analyzing factors such as facility locations, transportation modes, and distribution channels, businesses like yours can design resilient and cost-effective supply chain networks that adapt to changing market conditions. This approach is instrumental in expanding market reach, optimizing inventory levels, and enhancing customer service.

5. Multi-Echelon Inventory Optimization

Optimizing inventory across echelons of the supply chain minimizes costs while meeting customer demand. Multi-echelon inventory optimization techniques leverage advanced algorithms to synchronize inventory levels across warehouses, distribution centers, and retail outlets. By striking a balance between inventory holding costs and stockout risks, you can achieve optimal inventory management practices that improve service levels and profitability.

6. Collaborative Planning, Forecasting, and Replenishment (CPFR)

Collaborative planning, forecasting, and replenishment foster collaboration among supply chain partners to synchronize planning and execution activities. Sharing information and aligning forecasts reduces demand uncertainty, minimizes stockouts, and improves inventory turnover. CPFR initiatives enhance visibility and coordination across your supply chain, improving efficiency and responsiveness to customer needs.

Empower Manufacturing Excellence with SimWell

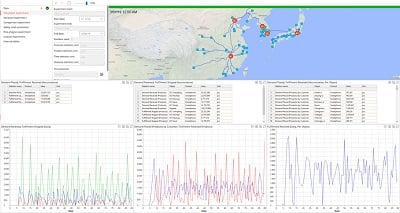

As a leader in modeling technology, SimWell empowers manufacturing enterprises to navigate the complexities of supply chain network optimization with confidence. We enable you to use advanced simulation and optimization tools to your advantage, creating models that help:

- Identify optimal supply chain configurations that balance cost, service, and resilience.

- Evaluate the impact of strategic decisions on key performance metrics such as lead times, inventory levels, and transportation costs.

- Mitigate risks associated with disruptions by simulating various scenarios and developing robust contingency plans.

- Enhance collaboration and coordination across supply chain partners through integrated planning and execution capabilities.

Supply chain network optimization is vital for success in today's competitive manufacturing landscape. By combining mathematical models, heuristic algorithms, simulation techniques, and collaborative practices, you can achieve operational excellence and thrive.

Unlock new opportunities for efficiency, cost reduction, and resilience in your supply chain operations with SimWell by your side. Get a sneak peek at our approach by exploring our supply chain network case study!

About SimWell

SimWell Consulting and Technologies is a global company specializing simulation, optimization, and digital twin technology. Our core mission is to unlock simulation at scale. We empower leaders and operators to maximize their current resources, optimize their operations, and elevate their performance with simulation. We build models of our customers operation, test scenarios, and predict how it will perform in a risk-free environment.

With SimWell as your partner, your team will have the tools to make confident decisions, optimize your process, and press fast forward on your business.