The One Thing Holding Supply Chain Master Planning Back

A Master Planner makes an incredible contribution to every team, and they are a unique breed of people. They are great project managers, have excellent soft skills, multi-task and manage risk all under a ton of stress. If they do well, it's business as usual.

If they make a mistake, everyone knows it. Supply Chain Master Planning is the backbone of an efficient organization.

Because of this we often think about the master planner's job as being a complex and stressful role. That is, that there is a lot on their plate, and that's just the way it is for every master planner. But it doesn't have to be that way.

There's one thing that every master planner is faced with that makes their job complex. Without this one thing, they'd have the easiest job in the company.

In today's article, discover the one thing that's holding master planners back. Help them manage this, and watch their satisfaction level and your profit increase at the same time.

What Is Supply Chain Master Planning?

Supply chain master planning is the act of coordinating production and inventory/transportation to meet demand. The APICS Framework defines master planning as a “group of processes that includes demand management, sales and operations planning, and master production scheduling.”

One way to understand the importance of master planning is to think about what would happen in an environment without master planning.

A World Without Master Planning

In a world without master planning, sales and marketing would operate in a silo. They might close a big deal with a short delivery window, and that key information would take a long time before it made its way back to production.

If production doesn’t know about the big order, they will continue production based on their general schedule.

Once production does get wind of the big order a few days after its closed, they’ll adjust their schedule to meet demand.

However, the raw materials won’t be there to ramp up production quickly enough. If they can’t ramp up production, they won’t make enough product to meet demand.

When a company can’t make enough product they can’t deliver to the customer on time. Ultimately they will lose the customer and lose money.

If you don’t have a great master planner, you’re losing customers.

If you have a great master planner, but you aren’t giving them the tools to predict something as complex as a supply chain, you’re losing money.

A World With Master Planning

Now, imagine an environment with a Rockstar master planner.

She’s having regular meetings with sales and marketing to understand what’s booked and what’s coming down the pipeline.

She’s meeting with production leaders regularly to discuss forecasts.

Production leaders know what to expect in terms of orders.

Finally, she’s working with distribution and suppliers to make sure they have enough inventory for production to make the product.

What Is a Supply Chain Master Planner

The supply chain master planner oversees the manufacturing environment, with their main focus on setting production schedules.

The master planner coordinates various departments within an organization, and even external suppliers, to ensure material is available, inventory is maintained, and production is keeping up with demand.

The One Thing Holding Supply Chain Master Planners Back

Master Planners have a tough job. They have a lot to do, a lot of people to coordinate, and a ton of pressure to deliver. While the task list of a master planner might have hundreds of bullet points on any given day, there’s one thing every supply chain master planner must overcome.

That one thing…is complexity.

Their job is complex. They coordinate everything to make sure the company meets demands. But “everything” isn’t what makes the job complex. In fact, “everything” would be easy if it weren’t for complexity. What makes their job complex is the variability in each step, their constraints on resources, and time.

Think about it – if we removed variability, resources, and time, the supply chain master planners job would be one of the easiest in the company. They’d simply follow a series of steps to coordinate production and demand.

But that’s not the real world. The real world has a lot of variability. Every company has limited resources. And time is always increasing the pressure.

The Impact of Variability On a Planner

Here’s how these pesky villains (variability, limited resources, and time) impact the master planners’ day.

Sometimes delivery trucks arrive on time, and sometimes they don’t, and the master planner has to build a schedule that works no matter what time the driver hits the door.

Sometimes machines break down for minutes and sometimes they break down for hours, and the master planner must coordinate around planned and unplanned maintenance.

Most of the time it takes X minutes to complete a task, but other times it takes 2X minutes to complete a task, and the master plan must schedule the next step regardless of process time.

That variability makes the master planner's job complex.

They have to know when the raw materials will hit the dock if they’ll have the right people to unload it, and how long it will take to move to production.

They need to know if a machine is down, how they can work around it, or what schedule change is necessary to meet their goals. They need a Plan A if all goes well, and they need a Plan B if not.

When they’re right? Everything is normal. When they’re wrong? People stay late to get the job done and leave frustrated. The boss gets on their back. The company loses money.

How to Help Master Planners Be More Efficient

The ability to understand the complexity of the system and manage the variability, resource constraints and time is why good planners are worth their weight in gold. It’s why the job is so important.

But most systems are too complex for even the best planners to predict how they’ll perform. When supply chains are complex and interconnected systems, it’s impossible for a person to consider all the variables and reliably predict how the system will perform.

People rely on heuristics, or mental models, to predict how systems play out. They use what they believe are the most important variables, which is derived from the way its always been and what they’ve seen in practice.

As you can imagine, there’s incredible bias in that decision-making process. This isn’t meant to sound negative, planners do an incredible job coordinating all of this complexity. The point isn’t against them; the point is that it is literally impossible for a planner to capture all of the variability and system interactions over time without the aid of a tool.

And one way to help them in their job is to provide a tool that captures the complexity for them. If they can capture the supply chain in a model and include all variability and system interaction over time, they can focus their energy on orchestrating the plan. If they don’t have a tool to capture the complexity of the supply chain, they will make inherently bias decisions and the process will be inefficient. The business will lose money.

Supply Chain Master Planning Software That Capture’s the Complexity of a Supply Chain

Simulation software is the most trusted approach to capturing variability and system interaction in a supply chain because it’s been proven over decades of use in dozens of industries and thousands of applications.

Simulation software allows a company to replicate their process in a virtual world and capture the variability and system interaction of the real world.

It then allows users to adjust input parameters like demand, inventory levels, or operations changes and run a what-if analysis to predict how the system will perform with the new inputs.

SimWell specializes in simulation and optimization. Whether you need the tools and support to do it in-house, or a team of specialists to do it for you we can help.

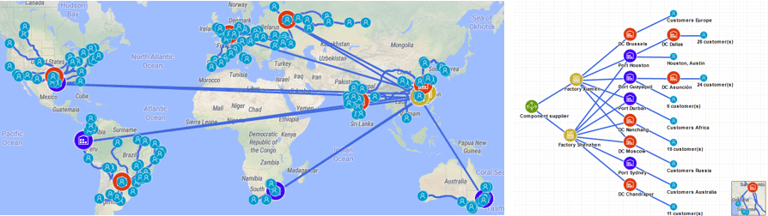

For supply chain master planning, we recommend anyLogistix because it combines best in class simulation and optimization with GIS. It allows users to quickly build GFA models with roads and use that as an input to run network optimization.

With a single click, it allows users to move from optimization to simulation and run what-if scenarios.

Help Master Planners Capture Complexity and Reduce Their Stress

Never trust a tool that says it can replace a master planner. Maybe someday when there’s a true, fully integrated, end to end digital twin solution. But even then, I fear master planning is too complex.

Without rehashing the last few sections, consider the demand side of planning. Master planners have to look at what’s booked, what’s forecasted, and what marketing has planned so they can truly understand the system or the demand. That’s an art as much as it is a science, so the master planner is key to organizational success.

While software tools won’t replace a master plan, they can help them get more done, improve their ability to predict outcomes in the system, and reduce the overall stress to minimize turnover.

About Us

SimWell is the North American leader in simulation and optimization solutions. If you need help capturing the complexity of your supply chain to aid supply chain planners, or you need to find the right tools to do it yourself we can help.

It starts with a conversation. Send us a live chat, or click Start the Conversation. We want to learn about your supply chain challenges and see how we can help.