Since 2020 change has been normalized around the world. Headlines on any given day read,

- Port of X is backed up days/weeks

- Import tariffs will be implemented on country Y

- COVID variant is causing new or extended shutdowns

- There’s a shortage of…

- Transportation costs are increasing

- Labor shortages are causing issues for…

- Natural disaster leads to mass evacuations in…

These headlines just seem to keep coming…so if we know change and disruption will come, why are organizations struggling to respond?

I’ve found that for a lot of companies, they don’t have the tools or the information to make an informed decision and respond quickly.

But it gets a lot easier when you have the tools that allow you to understand how a change or disruption will impact your operation. Really the only tool that can capture the complexity of a supply chain and help business leaders gain insights into their operation is a simulation-based digital twin. Read on and you’ll learn how supply chain simulation will transform your operation.

Why Traditional Supply Chain Tools Fall Short

If 2020 taught us anything, it’s that businesses that lack the agility to respond to change fall short. Supply chains have been built around forced process – which is great. The challenge is that it’s often managed by spreadsheets and optimization. These are rigid tools that expect the operation to perform within the framework developed. These tools lack the ability to provide insight into how a supply chain will respond after a change. As volatility increases the traditional tools like spreadsheets aren’t capable of capturing the complexity of supply chains. The more assumptions we need to make in a spreadsheet the less accurate it becomes as a planning tool. And the bigger the spreadsheet the slower we are to respond. Good supply chain leaders know they can’t rely on this information.

Losing Your Competitive Advantage

Over the last decade there’s been a shift in how executives view their supply chain. Amazon set a standard with 2 day shipping that gave them a competitive advantage…as long as you don’t need a product immediately it’s probably easier to wait 2 days than it is to drive to the store. Companies are making investments into their supply chain in order to create their own competitive advantage, and most have been doing a fantastic job…while the world was stable. Again, if 2020 taught us anything, it’s that businesses that lack the agility to respond to change fall short.

You Ought To Have a Way To See How Your Supply Chain Will Perform

There’s one thing we know for sure – supply chains will continue to be disrupted. The impact on the supply chain is that it doesn’t follow the status quo. The impact on the team is that they have to answer questions they may have never answers before. When a disruption like a hurricane or political event impacts a supply chain leaders receive questions like how will it impact our business? Where will we run out of inventory and when?

When there’s a sharp change in demand the questions look different. When will we run out of capacity and where? How should we store inventory over capacity? What are the secondary and tertiary impacts to the business? And most importantly - how should we respond?

If your leaders are asking questions like these and you aren't sure how to answer them you need simulation. At SimWell we help world class organizations model their supply chain so they can ask what-if questions and gain insights that improve their business.

When you have a simulation of your supply chain you gain insights you've never had before and move your business faster. When you don't capture the complexity of your supply chain in simulation you get stuck trying to analyze in a spreadsheet or making decisions based on gut feel.

How to Build a Supply Chain Simulation

If you’re a supply chain leader, this is the critical next step that you MUST meet with your team to clarify the most pressing business challenges and get an action plan to answer the necessary questions.

This is when you turn your questions into a supply chain simulation, and your simulation into actual insights.

If you’ve never done it before, you may be wondering what building a simulation model of your supply chain looks like, exactly.

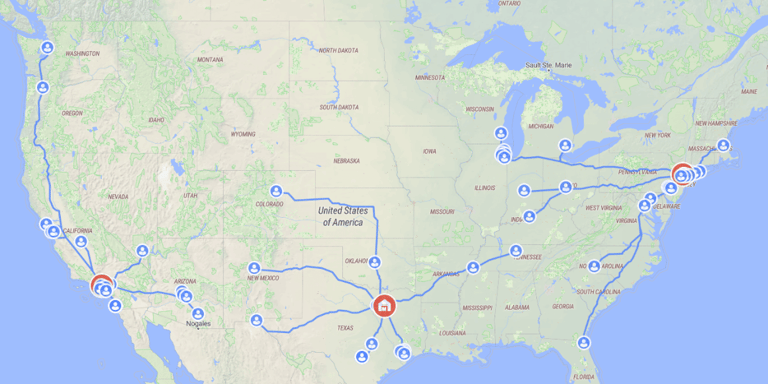

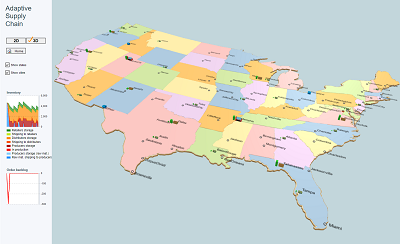

What we do is map your supply chain and use your data to create a model that captures everything unique in your supply chain. Then we start asking questions and using the model to understand the range of possible outcomes so you have the necessary insights to make a confident decision.

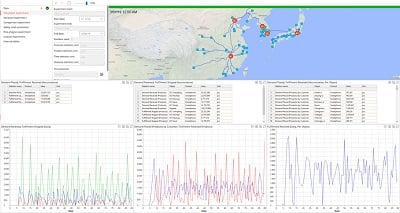

Then we connect the simulation to your real time data to create a simulation-based digital twin. Your team will think this is the most powerful tool to evaluate their supply chain, and you’ll save millions.

How to Turn Your Supply Chain Simulation Into a Digital Twin

A simulation model is often built to answer a specific question – like how do we manage inventory. A Simulation-Based Digital Twin allows you to answer ongoing questions – like what happens if our cargo is delayed at the Port of LA this week, or where should we keep excess inventory to minimize cost. The Simulation-Based Digital Twin is used to answer strategic, tactical, and operational questions.

Once you have a simulation model it’s quite easy to create the Simulation-Based Digital Twin. You’ll use the same model and feed it with real-time information that can be pulled from any system, database, software, IoT, and more.

Supply Chain Simulation Creates Agility Through Insights

The world is changing fast. Trailblazing supply chain leaders find ways to create agility and move their business faster. However, it’s not enough to just move. Of course, you have to move in the right direction. If you don’t have the tools needed to answer questions from your team, and it feels like your supply chain is falling behind, you need simulation. When you have a simulation model you create an agile, data-driven operation. When you don’t have simulation you use historic tools and gut feel that turn into less than optimal decisions.

If you’re a trailblazing supply chain leader interested in how to use simulation in your business you can book a call. The Supply Chain team at SimWell will be excited to learn more about your operation and challenges, and answer your questions on simulation.

About Us

SimWell is an engineering consulting firm specializes in simulation, digital twin, and artificial intelligence. We help trailblazing leaders capture their complex operations in a model so they can ask what-if questions and gain insight in their operation through simulation. With a model of your operation built by SimWell it will feel like you’re literally pressing fast forward on your operation so you can stop guessing and start making confident, data-driven decisions. Book a call with us at www.simwell.io.