What Is Greenfield Analysis?

Businesses can use a Greenfield Analysis (GFA) to determine the ideal number and location of distribution centers to successfully manage operations. Because of this, a GFA is typically used in supply chain design because it helps enterprises make more informed planning decisions.

What Is a Greenfield Analysis?

To better understand how a Greenfield Analysis works, imagine you’re the VP of supply chain at a growing company. During a leadership meeting, your team sets goals to optimize expenses to meet service level expectations and lower the company’s carbon footprint. This involves establishing new initiatives to minimize costs and improve resource management in the supply chain. You understand that the most expensive and environmentally impactful aspect of your supply chain is transportation. So what’s the next step?

Once you’ve identified the problem—transportation has a high cost and negative impact on the environment—you can begin to explore solutions. As an experienced supply chain management professional, you recognize that you can lower transportation costs and emissions by reducing the distance between your business and the customer. Although this solution may sound simple, your business can’t build a distribution center (DC) in every neighborhood.

A Greenfield Analysis can help identify the optimal number and locations of distribution centers to serve your customers based on demand, customer locations, products, and distances to and from the DC.

In short, a Greenfield Analysis helps you make better, data-driven decisions that will improve your supply chain.

The Benefits of a Greenfield Analysis

The overall goal of a GFA is to identify the optimal number of distribution centers and approximate locations for each distribution center to provide optimal service to your customers.

Conducting a Greenfield Analysis is the foundation to answer the following questions:

- What is the optimal number of distribution centers and factories for my supply chain?

- How many distribution centers are required to meet specific service levels?

- If we’re aiming to reduce costs, what is the optimal geographic location of our distribution centers?

- Which customers will be serviced from each distribution center?

- What is the right multi-echelon strategy?

- How resilient is my network? Will it be able to respond to future demand and supply changes or unexpected disruptions?

Conducting a Greenfield Analysis is almost always the first step in supply chain network strategic planning because it’s relatively quick and easy. You can also run a GFA when making changes to a supply chain or comparing an existing, real-world supply chain to an optimal supply chain design.

How to Build a Greenfield Analysis Model

The first step in conducting a successful GFA is correctly structuring your model. You’ll need to define customer and node locations, products, demand, and an overall objective for the model to work toward.

Once you plan your model, you can build it in a tool. One of the most common approaches to a GFA can be carried out using Excel. However, traditional Greenfield Analysis methods that use software like Excel typically offer limited features and options.

When compared to tools built solely for the purpose of carrying out GFA, this method is more time-consuming. It can take a lot of time to run an optimization model using Solver in Excel, especially when you’re looking at a real-world supply chain with multiple potential outcomes and unexpected disruptions.

Tools developed specifically for GFAs offer more functionality and faster runs. However, using this type of solution will improve the accuracy, speed, and flexibility of your model.

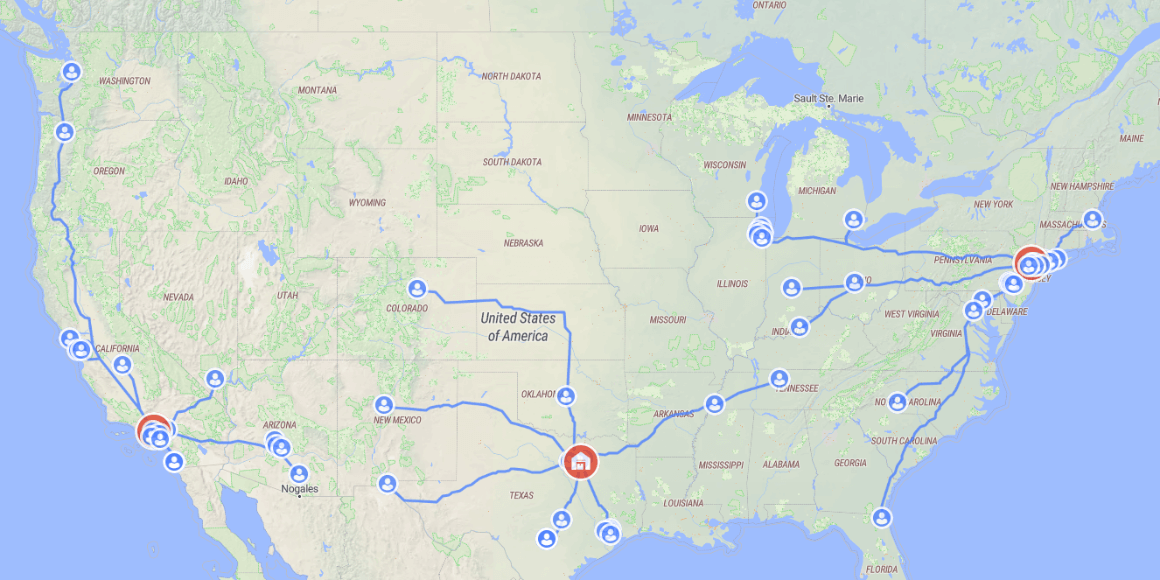

If you’re carrying out a GFA for a real-world supply chain, it’s helpful to use a commercial tool. SimWell specializes in anyLogistix. This software uses supply chain optimization and simulation for supply chain network design, inventory optimization, capacity planning, and risk analysis.

With anyLogistix, businesses can achieve lean, agile, and robust supply chains. With the ability to create a Digital Twin of your supply chain, businesses have access to powerful insights that optimize the supply chain planning process. This allows organizations to develop better strategies, using network optimization and simulation modeling to test and develop these plans.

Learn more about how to carry out a GFA using anyLogistix in the video below:

Using AnyLogistix for Supply Chain Design

anyLogistix combines best-in-class simulation (AnyLogic), optimization (IBM CPLEX), and geographic information system (GIS) integrations with an intuitive interface that makes it easy for anyone to use. This all-in-one solution allows businesses to easily analyze and improve their supply chain network from end to end.

This innovative tool is the only solution that combines simulation, optimization, and GIS into a supply chain design solution. If you’re interested in learning more about other use cases for anyLogistix, read this article about supply chain network optimization.

About Us

SimWell is the North American leader in simulation and optimization solutions. Need assistance with a Greenfield Analysis? We provide the tools and training for you to do it in-house, or we can do the work for you. Simply fill out this form. We’re ready to discuss your supply chain challenges and look for innovative solutions.

-1.png?width=768&height=512&length=768&name=Add%20a%20subheading%20(4)-1.png)